Date: 02-21-2026

|

Number of Hours: 4.00

|

Short Description: Back on the Ailerons (21-06)

|

With the flaps mostly finished and out of the way, I was able to get back on the ailerons. I primed the remaining skins, ribs and stiffeners. Once that was complete, I riveted the doublers to the main ribs. I tried back riveting this time, which was much faster, but still deforms the rib a little. I back riveted all the stiffeners and main ribs to the skin. Per the instructions, I put it all together in prep to drill the trail edge, but I’m not to keen on putting a bunch of holes in my table, so I may pick up some flat boards to put under the aileron.

Aileron main rib assemblies complete (26-047)

|

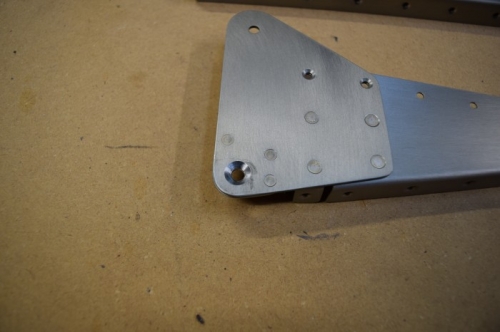

Large countersink added (26-049)

|

Aileron reassembled (26-050)

|

|