|

|

|

|

Wendells RV-6A

|

Date: 5-18-2012

|

Number of Hours: 3.00

|

Manual Reference: External Steps

|

Brief Description: External Steps 1

|

|

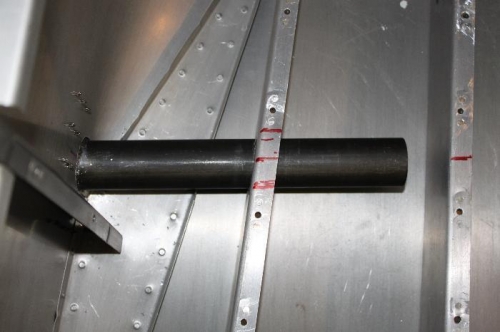

I guess time spent looking for the steps and the associated instructions count towards build time. No kidding, I spent about an hour rounding up those things. Paper in one place, steps in another. And, I have a lot of paper to sort out and file or trash, But, I found everything. Looks straight-forward. Center a 1.5 inch hole 1.625 inches aft of the middle web of vertical flange F624, high enough so the bottom of the 1.5 inch step tube rests on the web (or rivet shop heads of flat rib F623. The center of the 1.5 inch tube should be located 8.75 inches forward of bulkhead F606 web on the 2 inside floor ribs. What you end up doing is enlarging the outer hole to accomodate the weld bead so the plate goes flush to the fuselage. Dremel off a little at a time, test it, etc. When I finished, I marked up the plate, predrilled all holes except those that go through the F624. Once I got it positioned, match drilled, and clecoed then I used a pre-drawn line designating the existing rivet line in F624 and also marked the existing rivets that were in the way. Made slight adjustment to miss those and finished drilling. Of course, as I discovered once again, all is not the way its supposed to be. You can see the torque tube does not reach the floor rib inside and we wait while I see what Vans says after they look at the pictures I sent them. I've seen doubled up UHMW blocks with longer bolts. Waiting for Vans before I go further.

|

|

Still have to trim and bend the aft bottom corner.

|

|

WTF..

|

|

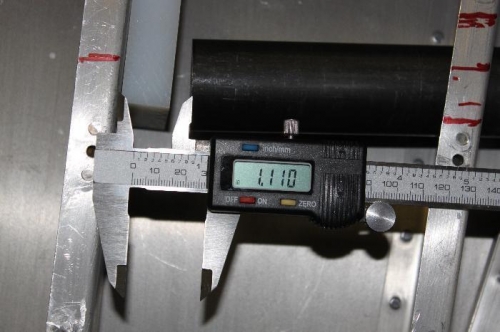

1 1/8 to 1 3/16 short due to the angle on the floor rib.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|