|

|

|

|

Wendells RV-6A

|

Date: 3-10-2009

|

Number of Hours: 2.00

|

Manual Reference: Pattern Drilling

|

Brief Description: Use templates to drill #40 pilot holes

|

|

Ribs A, 10,11,12 must staddle narrower thicknesses of main spar bars so in those spaces, the angles that get bolted onto the main spar as well as riveted to the leading rib web require .25 inch holes that allow pop rivets to be pushed all the way into the drilled #30 holes to eventually be set. Without those 0.25 holes, you can't get the LP4s into the rivet holes. The rivets would hit the angles you are positioning underneath the spar web along with the leading rib. So, you use a template to first drill the main rib end flanges. All the end flanges get 5 holes, one inch apart and no closer than 0.25 inches from the each end of the flange. I number the ribs from the fuselage (#1) to the outboard end (#14). There is an additional stand alone leading edge rib you letter "A". Ribs 13 and 14 get 8 holes drilled, still keeping the 0.25 inch margin from the ends. The bottom of the main ribs use a different template that drills four holes in ribs 5 through 14. Ribs 1 through 5 are the wing walk ribs and that end of the rear spar has a doubler bar predrilled with two holes already at each rib location. I will match drill through those doubler holes when everything gets mounted rather than use the 4 hole template. Those ribs get 3 holes in all. Rib 1&2 get an LP4 in the middle hole and ribs 3,4,5 will get riveted to the rear spar plus another brace through the middle holes soon.

|

|

Five holes - watch the edge distance.

|

|

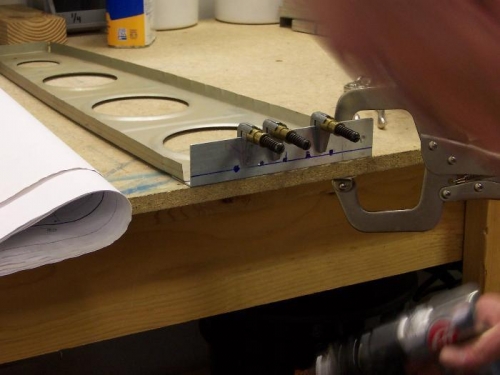

Clamped rib. Clamped Template. Drilled

|

|

Laid out first leading edge match drill job.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|