|

|

|

|

Larry Winger's 601XL Project

|

Date: 10-17-2006

|

Number of Hours: 5.00

|

Manual Reference:

|

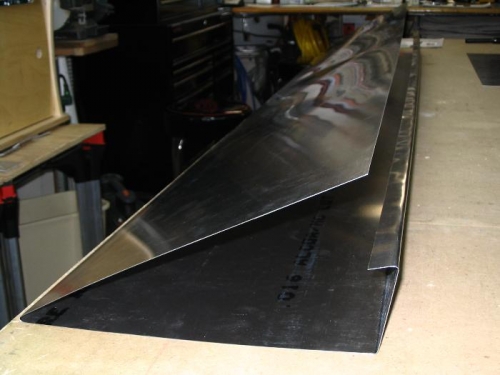

Brief Description: Made elevator ribs and attempted elevator skin

|

|

Cut, drilled, prepped and bent the .016" metal for the ribs. They are super easy to make, which is a good thing considering what came next. I decided to knock out all the .016" items tonight, which included the elevator skin. Because of the three bends, my bend calculator was of little help. I tested a strip or two of .016" before I got it right. I cut and marked my big sheet and Joy helped me with the actual bends. I started by putting in the top skin, the bottom skin, then the back. In each case I was sliding the metal all the way through the brake. By the last bend, the small flange was all that was sticking out the front of the brake, and 3/4 of the way through the bend, I could tell that I was pushing on the edge of the metal, not making a clean bend. I immediately tried to realign things, but it was too late. The result is a flange that is narrower in the middle, subsequently making the rear web up to 5mm too tall in the middle. When I redo this part, I'll start with the 20mm flange in a more traditional manner (small flange leading the way into the brake, not trailing).

|

|

Completed elevator ribs

|

|

The ribs in the end...before the widening rear web

|

|

A view of the malformed rear flange

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|