|

|

|

|

Larry Winger's 601XL Project

|

Date: 6-3-2009

|

Number of Hours: 20.00

|

Manual Reference:

|

Brief Description: Canopy frame and latch tube system in place

|

|

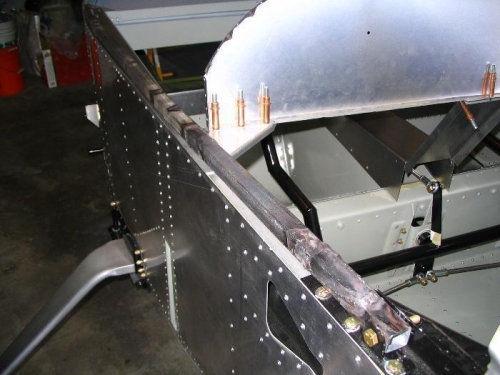

Unlike my usual practice, I just dove into this phase without noting every day's work. I did, however, keep track of my time and it took me roughly 5 hours to cut and fit the parts for the canopy frame, 12 hours to weld and tweak the canopy frame and latch system parts, and another 3 hours to install the latch tube system. The last remaining step is to install the actual latches and connecting arms, but that will be delayed until I can get the right countersunk bolts. By the way, learning to weld has been one of the most frustrating, and yet satisfying, parts of my project to date. I opted to purchase all my welded parts until now from ZAC, but based on this experience I would definitely weld almost all the parts myself if doing it over again as a scratch builder. The learning curve is steep and the required practice can be tedious -- really only because of the time it takes to cut and prepare steel for practice welding -- but once the light comes on, it actually becomes kind of fun. My only advice is to bring enough heat to the party. You've got to melt metal and keep the puddle dancing, which is a state that can only be reached and maintained with a well-adjusted neutral flame and plenty of gas flow. Contact me if you are thinking about welding, and I'll be glad to give you my other hard-knock learnings.

|

|

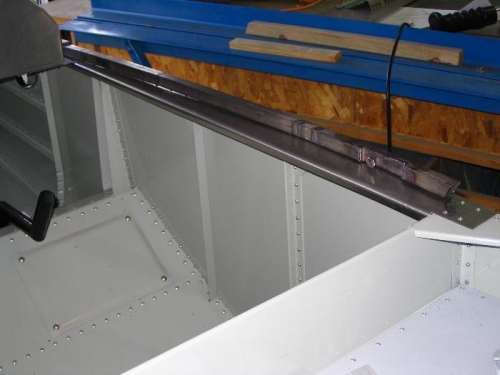

Passenger side canopy frame from the instrument panel back

|

|

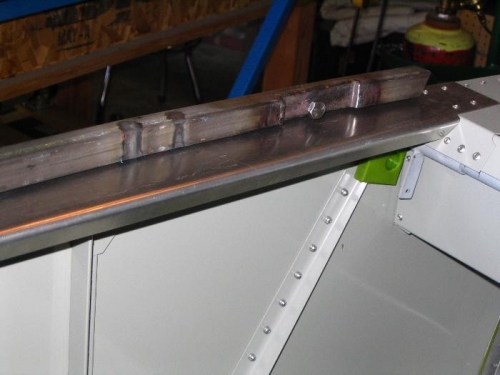

Closer view of the latch stud

|

|

Unpainted but very functional

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|