|

|

|

|

Wendells RV-6A

|

Date: 8-24-2012

|

Number of Hours: 6.00

|

Manual Reference: Canopy Hinge Fix

|

Brief Description: Canopy Frame 10 - Fix hinge arm problem..

|

|

Man, I need to get a welding machine and learn how to weld. I'm not cheap, but a local welder wanted $200 to cut the bad weld on the pilot side hinge arm where it attaches to the tube that acts as the support for the sun shield over the instrument panel. $200 bucks. No way. I decided to use the alternate fix that Vans ok'd. I made an .040 gusset and an .063 shim and shaped it to support the tube from underneath, wrap around to the back side and then forward along the hinge arm. The shim raises the hinge arm to level with top of tube avoiding a severe reverse curve on the gusset. Countersunk, primed and backriveted the gusset/shim /hinge arm assembly with AN426 AD4-7s. It was weird just holding the hinge arm in my hands. I had it pilot drilled to the front canopy frame but not riveted yet. Finished up and it works perfectly and I'm back in business. $200 bucks to do that small weldment fix. What a rip. I can now finish fitting the canopy skin, trim it, install the stiffeners and proceed with the canopy. One thing I learned is not to drill the canopy skin all the way across the forward canopy frame at one time. Drill the space between the hinge arms, then do the back tube. As you move outboard along the tube, the skin lays down flat, It pushes forward along the sides and slightly overlaps the forward skin. You take measurements and draw a trim line on the canopy skin from about 3 inches outboard of the hinge arm down to the fuselage side. If you do the forward drilling all the way across the canopy frame first, there's no where for the excess skin to go but up and I think thats what creates that all too common gap between the tube and the skin that frustrates a lot of builders. That's my story and I'm sticking to it.

|

|

Dremel cutoff wheel carefully cut the bad weld. Then vixen filed the weld off the tube top.

|

|

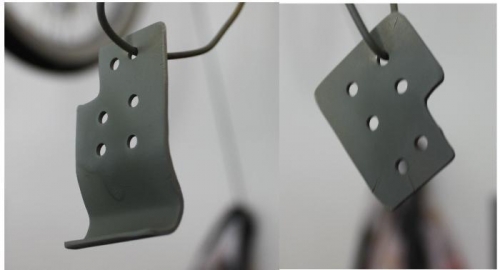

Gusset and shim fitted, drilled and primed.

|

|

Not setting the LP4s yet. Will wait. The gap on top of arm is due to not being drilled yet.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|