|

|

|

|

Dan's Web Site

|

Date: 5-26-2006

|

Number of Hours: 1.00

|

Manual Reference:

|

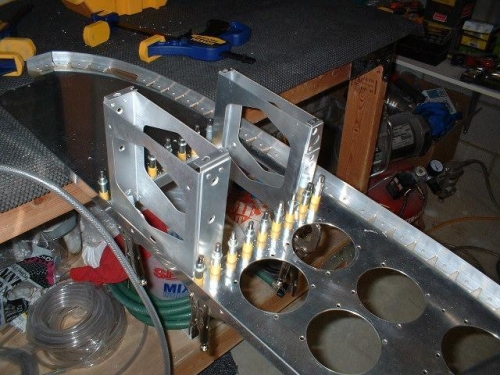

Brief Description: Fabricate / Drill Support Angles for Radio Stack

|

|

I spent far to much time today fabricating the support angles for the radio stack. I initially cut two 3/4 x 3/4 angles 8-3/4" long and then measured and drilled several #40 holes to attach these to the panel. I then clamped the angles to the panel and back-drilled the panel using the angles as a guide. I then countersunk the panel and decided to trial fit the radio trays.Here is where the problems started. The big hole was about 1/8" too wide. I can't believe it. I thought I had this perfect since I kept fitting the trays while I was doing all of my filing. What to do...I decided the only way to really fix this was to make a new set of support angles and use the holes that were now drilled in the panel as a guide to drill the new angles slightly closer to each other. The best way to get the spacing perfect is to clamp the trays to the angles first before clamping the angles to the panel.I decided to place the trays all the way to the left such that there would be no gap as viewed from the pilots seat. I debated on whether I wanted to split the difference and have a gap on each side but decided I didn't want to be reminded of this every time I went flying. I doubt the passenger will even notice given that the support angle will fill the gap. It's just rececessed by the width of the panel material is all. Oh well, I won't be redoing my panel because of this, that's for sure!Because of the limited access for all of the clamps, I had to place the new angles on the front of the panel in order to drill them using the holes in the panel as a guide. What this meant was that the angles have a reversed image of the holes that they need to have,,,kind of like a negative of the picture that I really want. Not to worry though,,,I'll just make a third set of angles and use the holes in the second set to drill the proper image on the new set. Whew, what a mouthful,,,but fortunately not difficult to do...

|

|

Pre-drilled support angles were used to drill the panel

|

|

Second set of angles clamped to trays and the front of the panel ready for drilling

|

|

Second set of angles drilled using the holes in the panel as a guide.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|