|

|

|

|

Larry Winger's 601XL Project

|

Date: 9-2-2006

|

Number of Hours: 3.00

|

Manual Reference:

|

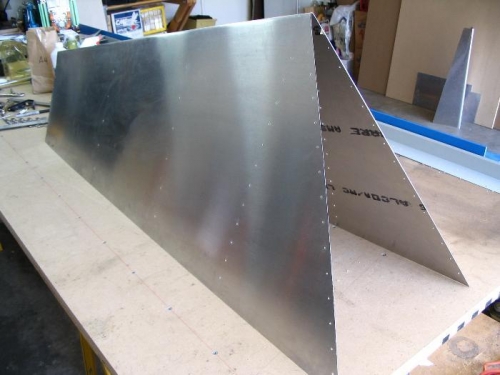

Brief Description: Trimmed bottom of trailing edge skin and pre-drill

|

|

I had oversized my skins on the advice of other builders. Now that I have a completed rudder skeleton to match, I found that my original markings (not the oversize to which I cut) were exactly right. Trimmed the excess, then removed the angled material at the bottom to equal the angle of the rear rib #1. I then carefully aligned the skeleton inside the skin, taping it to prevent movement, then marked the positions of ribs 2, 3 and 4 on the surface of the skin. Next, the skeleton was placed on top of the skin to mark the location of each rib's end point. This is needed to determine the location of the last rivet. This was followed by the rivet layout with pitch (spacing) of 70mm on ribs 3 and 4 and 40mm elsewhere. Finally, I taped the edges for alignment and drilled through all marked holes (except the end rivets), clecoing my work to the worktable for rigidity. Actually I clecoed all but about six of the rivet holes to the table, because I inadvertently started my drilling with a small corner hanging off the end. Ooops. No harm, however, and the part looks great.

|

|

Skin taped to the skeleton and ready for marking of the rib locations

|

|

Skin drilled through to the worktable -- mostly :)

|

|

The skin pre-drilled for attachment to the skeleton

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|