|

|

|

|

Wendells RV-6A

|

Date: 10-14-2012

|

Number of Hours: 2.00

|

Manual Reference: Elevator Push Rods

|

Brief Description: Push Rod 2 - F-690

|

|

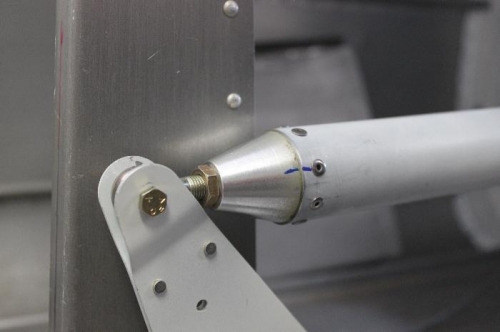

F-690 gets 8 holes in each end and cones get riveted on that have female threads. First, I trimmed it to 78.0 inches per plan. Used to be 78 3/8 but Vans revised the plans. Same drill. Used the V block. Drilled through tube #40 at 12 and 3 o'clock giving me 4 holes. Found middle of those holes and drilled through again twice to give me 8 hoiles. Then pushed cone in and drilled those 8 holes to #30 individually on the drill press. Made a matchup mark, pulled the cones, deburred, primed inside of cones and mating surfaces, reassembled, and riveted together, Put it together with the smaller tube and checked movement. Free travel to all limits, but my guess is when the contol surfaces are actually attached, the stick movement will not travel to any of the existing limits. So the drill will be when the elevators are attached and set in neutral position, you adjust the big tube bearings until the bell crank is vertical and each bearing is screwed in more than 1/2 way. Based on my experience with the plan measurements on the small tube F-689, I would not be surprised if the big tube is too long too. It looks about right, but we'll see.

|

|

Attached to bell crank for some testing.

|

|

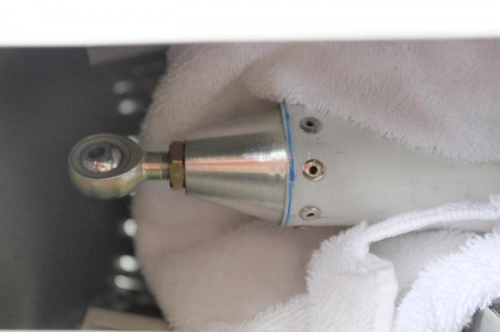

Made sure to lay towel to protect from scraping.

|

|

Aft end will connect to elevator horns.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|