|

|

|

|

Steve & Nancy Riffe

|

Date: 3-9-2016

|

Number of Hours: 4.00

|

Manual Reference:

|

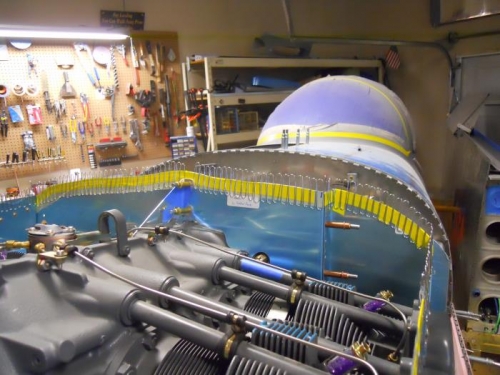

Brief Description: FAB work & paper clip marking

|

|

I trimmed some of the parts for the filter mount and decided I needed to look at more build logs. I found some better examples of how builders were getting the filter brackets to work. I trimmed the inside of the forward ramp as well as the back of the ramp. This allowed the filter bracket to better sit inside the snorkel. Then, I realized I should have made a “crossing” bend in this ramp as well—the top of the snorkel ends up not square at all—more on this later. I removed the lower cowl and the snorkel. Then re-installed the lower cowl and marked the ramp for the crossing bend. I had to remove the cowl again to get the ramp off—then made the bend, re-installed ramp, re-installed the cowl. Fortunately, I guessed real close on how much to bend, otherwise it would have been more repeat. I also made the slight bend in the side baffle. I really didn’t want to remove the cowl and ramp again, so I moved to trimming the baffles for the 3/8” to ½” clearance. I added 100 jumbo paper clips across the rear baffles and part way up the sides. Nancy helped me lower the top cowl in place, mash down on the paper clips and then remove the cowl. I measured .4” down from the top of the clip and marked the rear baffles and part of the side baffles. I removed the rear and side baffles, trimmed to the line, then finished on the scotchbrite wheel. Tomorrow, I’ll re-install the baffles and paper clip the sides for trimming.

|

|

My army of paper clips

|

|

Ready to check side for clearance

|

|

|

|

|

|

|

|

|

Copyright © 2001-2025 Matronics. All Rights Reserved.

|