|

|

|

|

Sid & Houston Mayeux Project

|

Date: 6-16-2014

|

Number of Hours: 2.00

|

Manual Reference: Cowling

|

Brief Description: Fixing the left side cowling gap

|

|

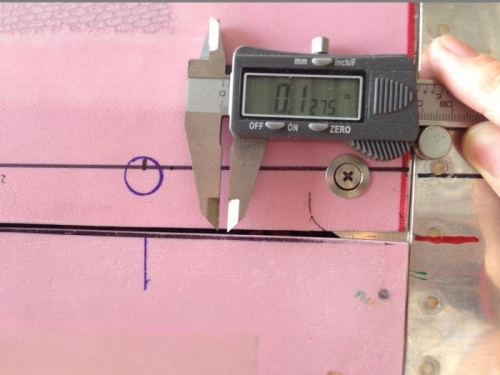

With all camlocs installed for the top/bottom cowl's connection to the firewall flange, I installed a camloc stud in every hole and installed both cowl halves to check the gaps between the cowls/firewall and the left/right cowl edges. The right side gap is perfect, but the left side gap is way too big. I'm looking for about a credit card's thickness, but 1/8" is too large.

I decided to build up the top half's edge. I sanded about a 1" thick bevel to the underside edge, giving the edge a knife-edge quality (without the sharpness). This increased surface area for the epoxy/fiber cloth layup to adhere to. I cut a 2' x 3" strip of sheet alclad, leaving the protective plastic cover in place, and used this as a backing facia for the layups. I then applied 5 layers of 9 oz. cloth the length of the metal strip, greatly overlapping the area with the gap.

The next day I removed the alclad strip and applied 3 layups of 6 oz. cloth to the outside surface. This made the build-up area WAY thicker than necessary and WAY taller. After another day to cure, I cut and sanded the build-up down closer. I installed the cowls to the aircraft, with the lower cowl edge overlapping the upper cowl edge. Using the lower cowl's edge as a guide, I cut the new split line into the upper cowl with a Dremel and a thin-cutter. I am quite happy with the new edge on image 3.

|

|

1/8" gap!!

|

|

Edge bevelled, 9 oz cloth layups

|

|

Much better!

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|