|

|

|

|

Jims Web Site

|

Date: 1-21-2010

|

Number of Hours: 4.00

|

Manual Reference: 6G1, 6G2,6B8,6B10

|

Brief Description: Fitted nose gear bottom bearing

|

|

1) Positioned lower bearing support 6B8-9 under the front of the aircraft, so bend in bearing was even with firewall front.

2) Drilled #40 pilot holes in bearing and clecoed.

3) Positioned nose gear bottom bearing 6G2-1 around nose gear leg 6G1-1, and slipped parts into rough position.

4) Shimmed back of nose gear bottom bearing until nose gear leg was approximately equidistant from firewall along its length.

5) Back drilled through lower bearing support into gear bottom bearing just far enough to mark the location.

6) Marked location of aft side hole of bottom bearing on side support.

7) Removed gear and bottom bearing from aircraft.

8) Drilled hole to clear AN3 bolt on side support.

9) Opened aft holes in lower bearing support to clear AN3 bolts, and temporarily bolted lower bearing support in place with 3 AN3 bolts.

10) Drilled marked positions on bottom of gear bottom bearing approx. 3/4" deep, using drill press and #40 bit.

11) Opened these holes to allow tapping for AN4 bolt, still maintaining 3/4" depth.

12) Tapped holes for AN4 bolt, and cleaned.

13) Fit checked nose gear bottom bearing on aircraft with lower bearing support.

14) Removed both.

15) Deburred, cleaned, and primed lower bearing support.

|

|

Initial fit check

|

|

Tapping gear bottom bearing

|

|

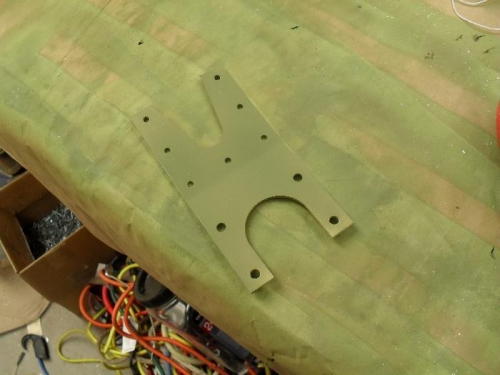

Primed lower bearing support

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|