|

|

|

|

Marlins Web Site

|

Date: 12-5-2020

|

Number of Hours: 20.00

|

Manual Reference: Sec 6; DWG 3

|

Brief Description: Fiberglass Empennage Tip Fairings

|

|

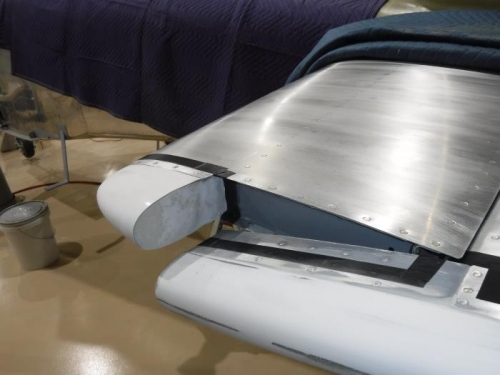

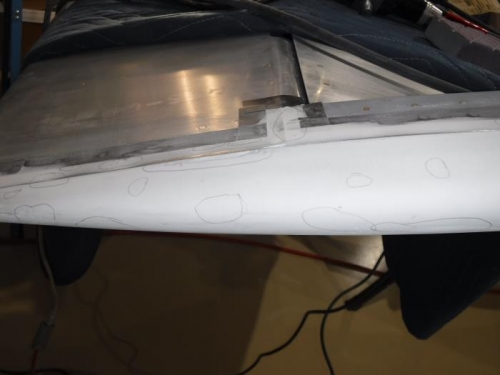

It’s been months since I’ve updated my kitlog. I’m sporadically doing fiberglass work which, like most people I know, enjoy the least of anything I’ve done on this airplane. In these pictures, I added a foam filler to the horizontal stabilizer/elevator tips and filled epoxy-cotton flox over top. If I had a little more experience and understanding of how to do fiberglass, I would instead choose option one; cut out the foam filler, temporarily bonded the filler in place, then covered with a layer of fiberglass cloth; finally applying a layer of microbeads and filler to finish. The method I chose, instead took approximately 65 hours of applying flox, sanding, reapplying, sanding, microbeads, sanding, filler sanding, sealer, sanding, more sealer, final sanding. It was very frustrating and doesn’t look as good as option one would have been; AND took approximately 50 hours longer to do. Additionally, the fairings as they came from VAN’s, all had little and large pinholes/pits, low spots, mars etc, in the gelcoat, so they had to be sanded and filled with a layer of microbeads. Due to my lack of knowledge of how to do fiberglass-work, I had to repeat this process many, many times to finally get it to the point of final filler and sealer.

|

|

Cotton Flox & Foam in tips

|

|

Low spots and pits in Elevator

|

|

Applied Microbeads/Peel-Ply

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|