|

|

|

|

Christopher's Web Site

|

Date: 5-10-2016

|

Number of Hours: 2.00

|

Manual Reference:

|

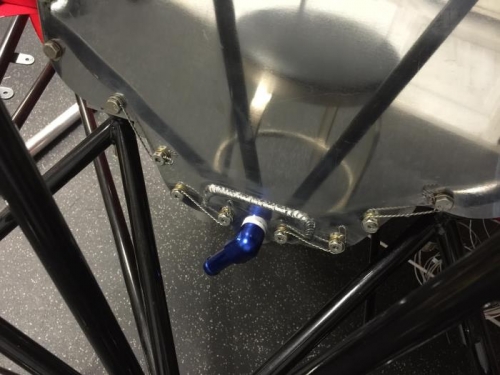

Brief Description: Safety Wire Tying

|

|

There is a tremendous amount of safety wiring required throughout the build of the helicopter. Vibration is a huge issue on aircraft, but with helicopters it’s even more of a concern. Everything needs to be secured with Loctite, lock washers, nylon locknuts, castle nuts & cotter pins, etc. In many cases, you can install bolts with drilled heads when a bolt is fastened directly into a mass without a nut, such as the engine. There is a specific procedure as to how to safety wire these bolts so they won’t come loose. Having never done it before, YouTube was a perfect source for education. After viewing multiple videos, I got to work with my special safety wire pliers and recommended thickness of wire.

You are looking for 7-10 twists per inch on the wire, and a bit tighter twist on the tail, which is then bent back up to avoid snagging and cutting an unsuspecting mechanic.

I waited this long on the process to wire tie because as I have found out and confirmed, when you think you are on the finial assembly of a item, there is still a good chance that you are going to have to remove it again for some reason, which means you’ve wasted a lot of time safety wiring over and over again. I decided to wait until I was going to lose access to the bolts before I performed the wiring tying.

Below are some examples of my work.

|

|

Engine Fan

|

|

Oil Sump Cover Lower Bolts

|

|

Alt arm...need to get in there now

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|