|

|

|

|

Tom's Web Site

|

Date: 11-14-2009

|

Number of Hours: 5.00

|

Manual Reference:

|

Brief Description: Cowl Top

|

|

Trimmed up the instrument panel flange. Debating on leaving it as, sitting a little higher the flange makes it much easier to R&R the panel, so it is trade off of "near perfect gap" or easier to R&R instrument panel.

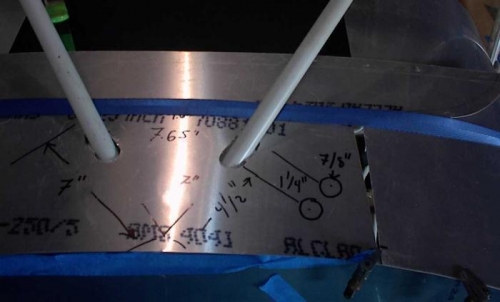

Scrap aluminum for laying out the top slots in the tubing.

Simple, once you've done it!

On the aluminum, lay out a triangle. Legs A = B = 7" (intersection is just in front of the firewall, btw -- you'll see the upper middle engine mount hole on the firewall as a reference point).

Now Leg C = 7.65". A & B have an intersecting angle around 65 degrees. The 7" length for the A & B legs is just to make a convenient distance, nothing special about that length, but allows for a simple measurement that is not removed when laying out

From the intersection of A & B, mark back 4.5" Then again a 1.25" further back. That is the center of two holes. A unibit that is 7/8" diameter makes quick work, trim out the area in between the holes. Slice the panel to slip around the tubes. Done!

Note the front needs to be trimmed to the firewall (hard to see in the photo. Image 2 -- I had drilled the holes 1" (easy mistake with a Unibit drill) for all four holes, and there is a gap around the tubes, hence 7/8" to be correct.

|

|

First attempt and second attempt

|

|

scratch piece to get layout correct

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|