|

|

|

|

Traci and Tom's RV-7A

|

Date: 10-30-2013

|

Number of Hours: 1.00

|

Manual Reference:

|

Brief Description: Rolling and finally riveting the rudder leading ed

|

|

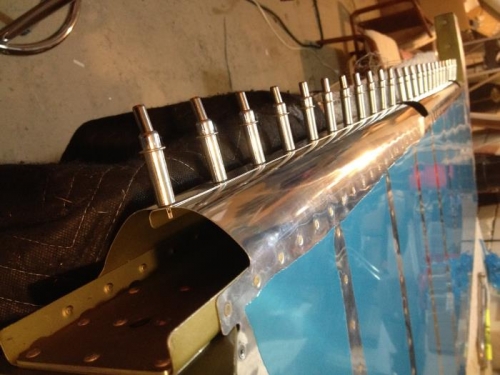

Once the flanges are rolled enough, they need to be lined up and clecked in place. As all the other holes, they need to be match drilled with the #30 drill bits, so you need to swap to the larger clekos as you go along.

I curled the last 1/4 to 1/2 inch of the flange to try to get a tigher flat fit once the overlap was in place. Drill, deburr (just rub some Scotchbrite on the hard to access inside) for a smoth hoe - or as close as I could get inside the flange. I know if I didn't deburr and smooth the edges of the evelvator flange, I would have cut my fingers. Btu I did smooth them done enogh!

Next, I took out every other cleko and blind riveted the flanges together. The flanges fit pretty well, but still had a few "pooched" areas between rivets. Again, this is a part of the plane that won't be seen - unless the builder knows where to look!

|

|

Rolled, yanked, and cleckoed in place.

|

|

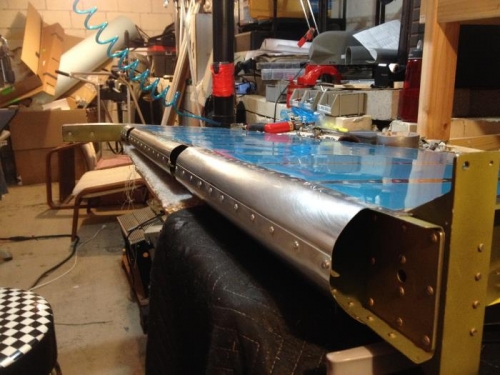

Drilled and blind riveted. Looks good other than a very few bulged areas

|

|

When done, I had to admire my work. More airplane in my backyard- and looks like it!

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|