|

|

|

|

Steves S-20 Build Site.

|

Date: 1-5-2019

|

Number of Hours: 5.00

|

Manual Reference:

|

Brief Description: Lower Cowl

|

|

Today was trimming and fitting of the lower cowl.

Others had told me that things will move as the cowl is trimmed, and the trick is to go slow. I was not sure what they meant by saying it will move. I learned that when the cowl is first slipped into place it does not fit well and as small parts of it are trimmed it will start to settle into place in the joggles, and will start to flex slightly into a shape that better conforms to the plane. As this takes place on one end, the other end is moving around, Making large cuts will not fit once settled in, so working in very small sections and taking your time pays off in the end.

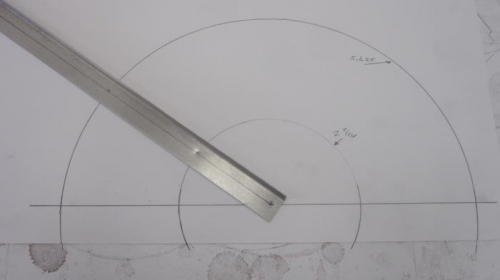

I started by measuring the spinner and the engine hub. I made a paper template, then trimmed the front of the cowl to keep it perfectly centered on the engine hub. This is a deviance from the RANS instructions, but it worked well. A couple of spring clamps held it in place against 3/8" spacers on the spinner back plate.

I spent a couple of hours getting the bottom corners trimmed to fit the joggles and installed 2 cleckos to hold it in place. From here I worked in 3" long sections to get the cowl wrapped up around the corners and onto the flats of the fuselage sides. Once here, I was able to make the rear edge cut all at once.

This is dirty, itchy work. A dust mask was an absolute necessity...

|

|

Paper tempate of prop hub centered in spinner diameter.

|

|

prop hub clearance cut into cowl.

|

|

Bottom rear corners trimmed, working up the sides.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|