|

|

|

|

RV-6A - GBC

|

Date: 10-16-2010

|

Number of Hours: 1.00

|

Manual Reference: N/A

|

Brief Description: Lycoming Models - research

|

|

Abraham Lincoln once said, "Calling a dog's tail a leg, doesn't make it a five-legged dog. It's still a tail." And, the Lycoming corollary 'adding F/I to an O-360 doesn't make it an IO-360, just an O-360 with F/I added.

Makes sense now - it will still be an "O-360-A3A" (180HP, parallel valve, wide deck chrome) with fuel injection added, and not an IO-anything.

Talked to Airflow Performance and looks like conversion is a three-part process which involves:

1) an upgraded mechanical pump,

2) high performance fuel pump, and

3) the injectors/spider, plumbing etc.

The plumbing seems to need either specifically designed to 'return' to tank, or compensate somehow to allow 'non-return'. Either way, there is a provision for it. I'll be able to do the appropriate plumbing. The injectors will install where the 'primer' plugs would normally fit in the cylinders.

Reason for the F/I conversion is to simplify flying (no carb heat), safety (no venturi icing), better starting (no priming), and fuel economy (leaning and flow control). With a F/P prop, F/I keeps it simpler. Better solution for a low-time pilot like me, and should be safer.

The engine is from a Cherokee 180, approx 3200 TT, 680 SMOH. Had a prop strike . Excessive run-out on flange and the starter housing cracked/gouged from ring gear. Mentally I'm prepared for crankshaft replacement, new starter, ring gear, and 'normal' supplies to re-assemble. Overall appearance doesn't suggest specific problems otherwise, but parts will be evaluated thoroughly.

|

|

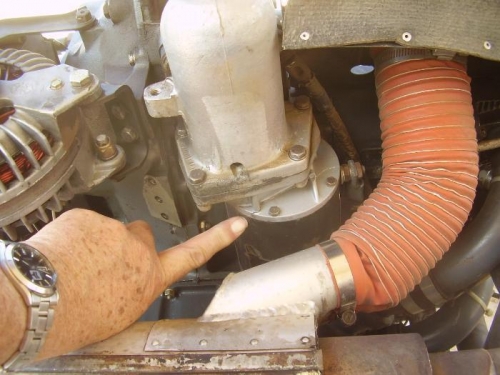

Crack in housing - starter

|

|

O-360-A3A complete

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|