|

|

|

|

GA Aerospace’s Web Site

|

Date: 2-24-2018

|

Number of Hours: 48.00

|

Manual Reference:

|

Brief Description: Skeleton dimpled

|

|

Members: Daniel Martinez, Ismael Romo, Jose Guerrero

With empenannage team: Daniel Ruiz, Ismael Ramonet, Ulises Valle

Absent: 0

Today we resume the work making dimples with the squeezer tool in the ribs (A-905-R and A-905-L) that will be on the sides, in the most critical areas where the squeezer could not be used due to the dimensions of the pieces, then we use a piece of prefabricated soft steel to make the dimples.

The squeezer was also used to make the dimples in the upper and lower skin that would be assembled in the skeleton of the piece. The skins were then fitted to the spars with the help of clecos # 40, and the flat head rivets were used in each dimple.

For the piece CP-4 it was necessary to fasten it with clamps to be able to make perforations in it and then attach it to the skins, once the perforations were made, each one of them was drilled to allow a good job when being riveted.

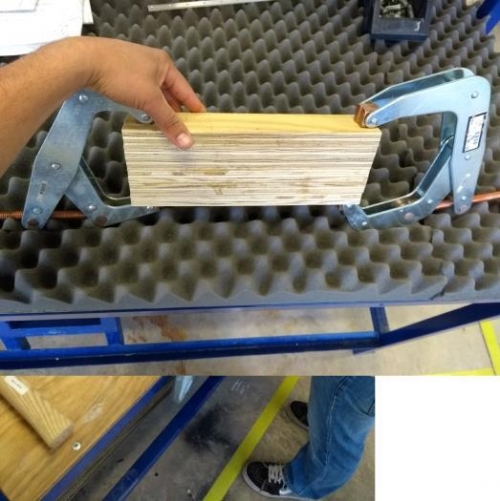

The team required to build a wooden accessory with dimensions of 2x4x11-1 / 2, in which special resistol was used to apply in each section of wood that will result in our piece, also a pair of large clamps was used to keep it pressed until that will manage to dry the glue. In this accessory the spar was placed and secured with clamps to be able to work on the piece at the moment of putting on the rivets or riveting the skins.

At the beginning of operations, some details were presented, for example, to make dimpling in the most critical parts of the ribs, for which the special bar was used to correctly parse the dimple. And also he was very careful not to create scratches on the piece when working inside the piece once it was fixed on the wooden tool.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|