|

|

|

|

Sonex 815 Build Logs

|

Date: 2-1-2008

|

Number of Hours: 3.50

|

Manual Reference:

|

Brief Description: Cowling installation

|

|

Took about 1/2 hour to tape the cowling back on, make up the oil cooler inlet pattern, taped that on and traced around it. Took about 1 1/2 hours to locate and cut the hole for the gascolator, cut out the oil dipstick hole, and the oil cooler inlet. Used a rotozip bit in the dremel for the gasco and dipstick holes, then finished these off with the small grinding tool in the dremel. Used the cutoff wheel for most of the oil cooler inlet, then finished off with the small grinding tool. Also smoothed off the gear leg openings with the small grinding tool. Took another 1/2 hour or so to make tracer lines for the upper firewall holes, tape the cowling back on and mark the upper firewall holes. Rest of the time (about an hour) took the cowling back off put the side hinges in place, drilled the upper firewall holes to 1/4" for the Southco's, taped the RH cowling back on, then drilled through the hinge from the inside out using the right angle attachment on a 12" flex extension, and also using the 12" drill bit in the 12" flex extension. Took the RH off, put the LH on, and drilled through the hinge from the inside out using the 12" bit on 12" flex extension. Didn't get all the holes, but at least the hinges are located.

|

|

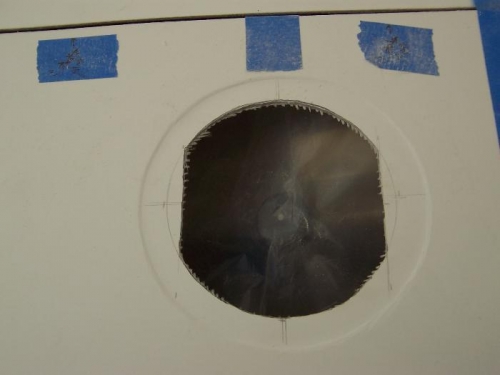

Oil dipstick and oil cooler inlets cut.

|

|

Oil dipstick through the hole.

|

|

Rolled it out for some photos.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|