|

|

|

|

Serenity

|

Date: 7-6-2007

|

Number of Hours: 1.50

|

Manual Reference:

|

Brief Description: drilled left aileron

|

|

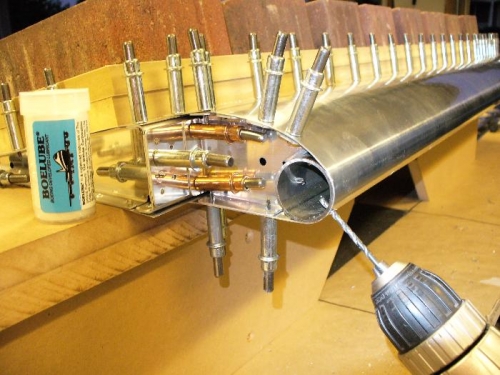

Everything drilled while being held dead flat. The stainless stell tube has 13 holes to be drilled, so I tested some bits after others reported going through a bunch. First brand - Tool Shop cheapy. Lasted for 3 holes - sucks! Next was Irwin Black Oxide - it went on and on. In fact, it finished the other 10 holes, and did the 13 on the right aileron. Even at the end, it was cutting properly (no chipping, still emitting curled shavings). Awesome bits. I never did get to test the Vermont American Sidewinders. Remember to liberally use cutting oil or beter yet - Boeing's Boelube (see in pic 1). For the trailing edge, I used the 12" drill with my old wood 84 degree template (pic 2), since the drill angle needs to be perpendicular to the chord, not either the upper or lower skin. I would then just cleco into the wood table. The underside spar was easily reached witht he 90 degree angle drill, since I didn't want to move the weighted assembly.

|

|

Have some extra 1/8" drills handy for the stainless steel!

|

|

Trailing edge being drilled, using old wood guide from empennage.

|

|

Another chance to use the Avery 90 degree drill

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|