|

|

|

|

Carl Bells RV7A N947CB

|

Date: 1-9-2008

|

Number of Hours: 3.00

|

Manual Reference: Electric trim Dwg

|

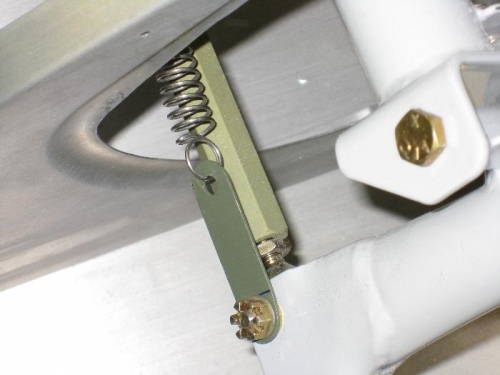

Brief Description: Aileron trim hookup

|

|

Ok, this may be overkill, but I just couldn’t use safety wire to do this hookup, it just seemed too crude. So I went into my radio control parts and decided on some heavy duty push rod ends from my 30% scale planes and used them for the attachment to the springs. These are adjustable to some extent, allowing for about ½” smaller or larger tension distance on each side. After hooking them up, I had to shorten them from 5” to about 3” to keep tension on both sides, but I’m not sure this is right, so I’ll email Vans and ask about the tension. In the plans that come with the trim, it reads slight tension. It seems too tight, but if I use less tension, one side droops completely when deflecting the stick to full right or left aileron, and that doesn’t seem right either. Hmmmmm

FLASH- I didn't like the tension on this set up because it goes slack in some positions so I called Vans. They said to put the stick to the uppermost forward-left position and the trim full left and then wire the spring into place with slight tension. Then do the same thing the other way. This is so there is never any slack, but the tension springs are really qute streached, but Gus said this is not noticable flying. The net is the adjustable rods are coming out and since the wire length is now 1 1/4" I will put in a couple of 50lb test fish line clips.

|

|

Botton clip with 10 degree bend - not final hardsware

|

|

Current hook-up to get to no slack at full forward & left or right stick

|

|

What I wanted to do

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|