|

|

|

|

Carl Bells RV7A N947CB

|

Date: 3-1-2008

|

Number of Hours: 3.00

|

Manual Reference: Dwg 34

|

Brief Description: Re-making the tunnel cover (See 10/24/07)

|

|

I never liked the way the original tunnel cover fit, so I decided to make it over. For the details on how to make it you can go back to the plans and my write up on 10/25/07. If however, if you want the part to fit. here is how to do it, your mileage may vary. Make the main side pieces form the Z extrusion per the plans, except measure the distance between the flap motor support bracket and where the bend starts on the seats. Change this dimension of the foot of the Z extrusion and modify the others to get a good fit in this space. DO not drill any holes yet, rather, match the hole in the seat pan to the extrusion after fitting the extrusion in place. Cleco the Z extrusion in place and make the .040 cover the measured width of the two Z extrusion clecoed in place. Bend the cover plate to fit the seat pan slope and keep it long enough to go from there to the flap motor channel. Drill the cover to the Z extrusions in place and after marking the locations of the rivets. This ensures it will fit perfectly, rather then trying to make it fit from the plan dimensions. What a difference, no oversize holes or twisting the cover to make it fit. This took maybe 2 hours total, so if your cover is way off, this is no big deal and costs less then 10 bucks to remake it to fit.

|

|

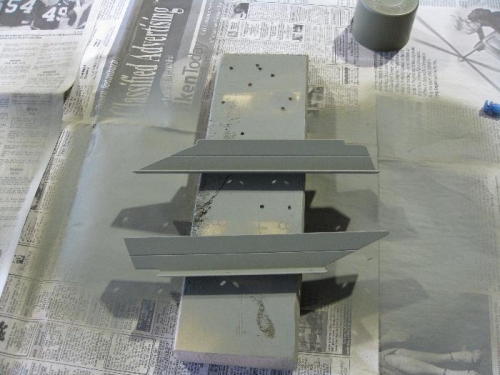

SIde frames

|

|

Close up

|

|

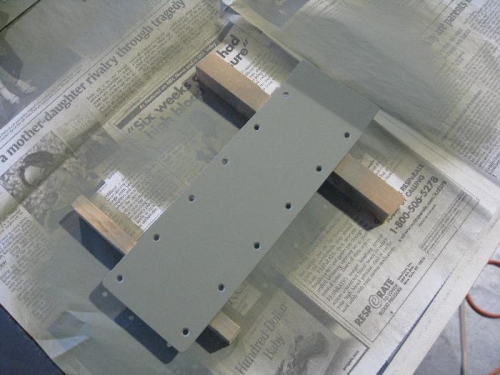

Cover plate

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|