|

|

|

|

Carl Bells RV7A N947CB

|

Date: 2-27-2008

|

Number of Hours: 5.00

|

Manual Reference:

|

Brief Description: Getting the ailerons in plane

|

|

I was disappointed with the alignment of the aileron on the wing, and after reading Matronics and VAF, I found many builders have had the same experience. Since the holes are punched and the dimensions are fixed in the planes for the hinge bracket, there is an issue some where, and not necessarily with the builder. A lot of builders are flying around with ailerons that are not in plane, meaning either a little high or low. BTW, I looked at 3 and they all had a high aileron on one side on the other or both. So, there is an easy solution, buy a new hinge bracket with out holes and move the holes up or down to get your aileron in line.

I called Vans and talked to Ken. What a great guy by the way and very knowledgeable. He said that I should wait until test flying and see if one wing or the other is heavy and adjust them at that time. He also said the sheet metal airplanes are not perfect and there are some variances, and that it really isn’t too far off, just slot the bracket a little and move the aileron in line and torque the bracket down. I suggested a fix would be F-XXXX without holes and I could move the holes 3/32” to bring the aileron into plane. He said brilliant, we have them in the RV 3 kit (not pre-punched) if you want your plane to be PERFECT.

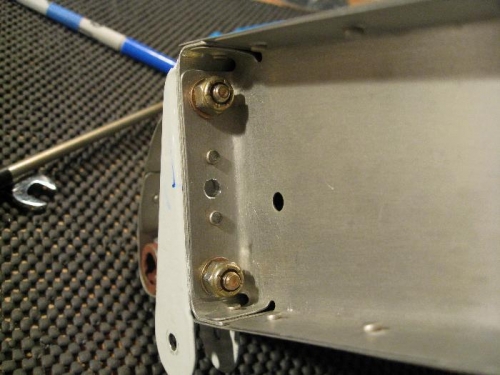

Ed Booth, my technical advisor stopped by, he also thought my idea of buying new F-xxx without holes and moving the holes to the right location was a good one. Then I said, how about slotting the brackets and adjusting it that way. Together, we decided that would be good if we added a third drilled hole in the middle between the slotted holes to lock it all in place. I think this is a really good fix, it is just as strong if not stronger and it allows a perfect adjustment, yet the third hole locks it all in place. The only downside is the weight of an extra AN3 bolt. It’s done, and the aileron is right in trail. If you have this issue, this is a good fix for up to 1/8”. After that, the bolt head will not cover the slot and the edge distances wil

|

|

Slotted hole for adjustment

|

|

Third hole drilled after adjustment

|

|

All done and all lines up

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|