|

|

|

|

Brad Wilkinson, Bearhawk #1062

|

Date: 7-5-2008

|

Number of Hours: 2.00

|

Manual Reference:

|

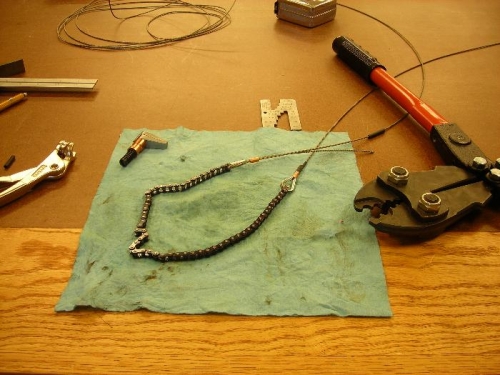

Brief Description: Trim Cables

|

|

Made up the cable ends at the trim chain. The 1/16" cable uses a "C" Nicopress oval sleeve, which only has one big full-width crimp, not three like the 1/8" cable.

Incidently:

After making several cable ends, I have found that if you put about a 3/4" piece of heat-shrink tubing on the free end of the cable, and cut it at 1/2" from the sleeve, you get a much cleaner cut with less unraveling of the cable. I know this seems like common sense - but I have high quality cutters and they cut very cleanly with no fraying or unraveling on normal cuts. But the stresses in the cable up close to the compression sleeve causes it to spring apart some when you cut it. This method stops that a good bit. Then when you slide the final heat-shrink over this it doesn't tend to grab strands and let them poke through. I was initially using two pieces already slipped on the cable to try to make up for this, but it wasn't working that great once the cable frayed. When I slipped the first one over the two cables together after cutting the free end it was hard to keep the strands in if you moved them at all. Then I went to using a 3/4" piece over the cut end by itself, leaving a 1/4" of tubing free, and sliding on a 1" piece second (this was already slipped over the cable) - and this worked better. But cutting the cable with the heat-shrink already on seems to work best. I was avoiding this so as not to waste the heat-shrink. It's about a 30 or 40 cents per foot, so now I'm wasting at least a penny or two every time!!

|

|

Making the ends

|

|

Close up, one done

|

|

Finished Chain-Cable Connections

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|