|

|

|

|

Todd's Web site

|

Date: 1-1-2006

|

Number of Hours: 3.50

|

Manual Reference:

|

Brief Description: Bending the rudder trailing edge and prepping rudd

|

|

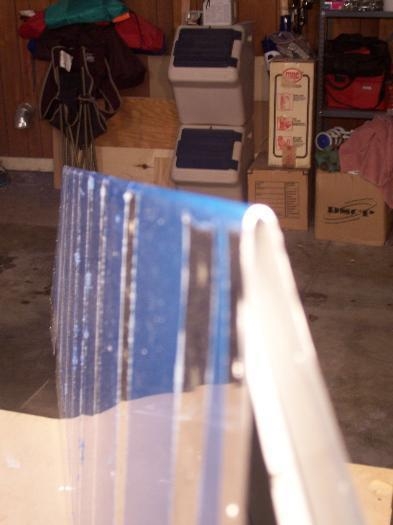

Went to Lowe's and bought a nice and straight 2x8x8 and some hinges. I cut one piece 49" and one 47" to have some "handles" on the side. I installed the hinges so there was a 3/16" gap between the planks, and that seemed to have worked perfectly for forming the trailing edge. I would have preferred to get the pieces planed, but I dug through the whole pile to find the straightest one in the first place. I think before I do my elevator skins, I will have a friend of mine run them through his planer.

The trailing edge turned out straight as an arrow. But when I cleko'd the skeleton to the skin, a slight bow formed about 1/3 the way up from the bottom. I was perplexed. Image 2 was taken at an angle so you can't appreciate how straight the trailing edge is in the photo with skin un-installed. But once installed, and looking from the same direction, you can see where the bottom 1/3 of the edge tails slightly to right, enough to cause about a 2mm gap at the apex of the bow on a 3' straight edge. Now I may be being picky, but it concerned me enough to call the Van's tech support and inquire about it. They said some oil canning is somewhat common in the rudder since there are only 2 ribs supporting it, and that it may all straighten up when it's riveted together. They said the important thing aerodynamically speaking is making sure the skins skins are flat and don't bulge near the trailing edge, as discussed in the instructions. As long as that is OK, they said the slight curve in the trailing edge won't cause any aerodynamic problems, and reiterated it was quite common. It still bugs me, but it eased my mind.

I completed all the match drilling of all the rudder parts, before I was called away....

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2025 Matronics. All Rights Reserved.

|