|

|

|

|

Sid & Houston Mayeux Project

|

Date: 9-21-2014

|

Number of Hours: 3.00

|

Manual Reference: Cowling

|

Brief Description: Cowling heat protection

|

|

I'm really interested in making sure the lower cowl doesn't get baked by my exhaust systems, so I followed procedures spelled out by the folks at Vetterman Exhaust in a Spring 2014 Kitbuilder Magazine article.

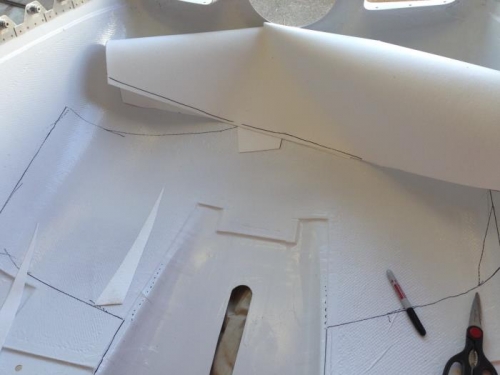

First, I checked the clearance between my cowling and all sections of the exhaust system: My tightest clearance is 1", which exceeds the 1/2" minimum gap. With the lower cowling installed, I reached inside with a black sharpee and traced on the cowl the general area that encompasses the exhaust system's area. After removing the cowling, I used white posterboard to draw templates of that exhause area.

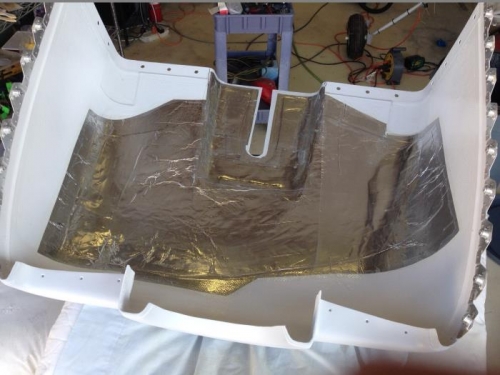

With the posterboard template, I cut out sheets of Fiberfrax, a ceramic cloth 1/16" thick with great insulation properties. I cemented these to the cowling with Pliobond, then covered this area with thick self-adhesive aluminum foil from Aircraft Spruce. I used a plastic squeegy to make the foil lay flat on the fiberfrax. I extended the foil beyond the Fiberfrax's edges by 3/4" to 2". Finally, I brushed clear epoxy onto all foil edges with an acid brush to seal the edges from oil, curl-up, etc.

|

|

Drawing out the template

|

|

Fiberfrax and foil installed, sealing the edges

|

|

Lower Cowling heat-protected

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|