|

|

|

|

REX'S WEB SITE

|

Date: 6-5-2016

|

Number of Hours: 6.00

|

Manual Reference:

|

Brief Description:

|

|

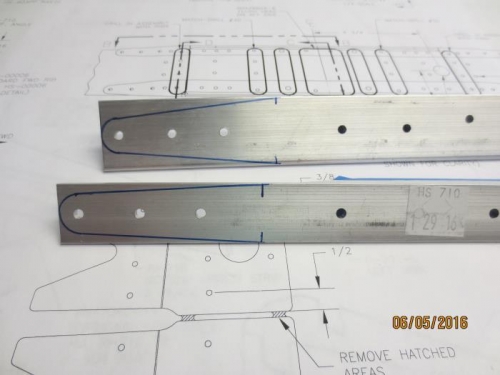

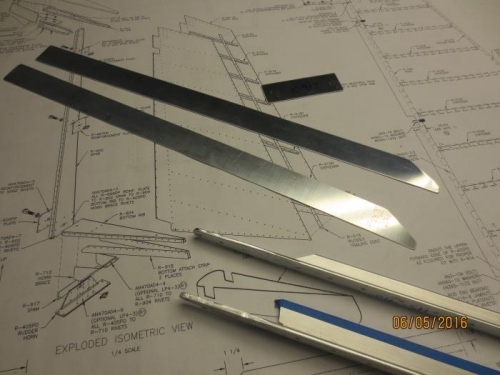

My neighbor Gary is an aviation enthusiast and gets to build a full sized airplane vicariously through me. He generously donated the use of his bandsaw to the project. After finding the right saw blade through Van's Airforce, (here is a link: http://www.sears.com/craftsman-1-4-x-80-in-band-saw-blade/p-00902625000P ) I was able to cut out R-917 shim and 2 R-918s.

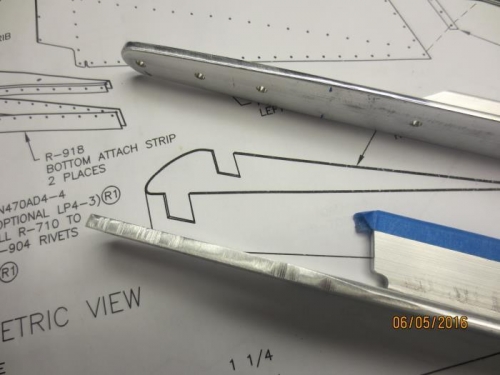

Then I set to work trimming HS-710 and HS-714. These are thick angle pieces to reinforce the forward spar. I drew the tapers per the plan detail on the flat bottom of each piece. First mistake. Then to see the cut line I fed each piece on the thin angle top (the blue tape edge in image 2). Second mistake. Then, to avoid lots of filing and bench grinding, I cut as close the line as possible. Mistake three. By feeding the piece upside down, it was impossible to keep it perfectly level, so some of the cuts left blue line on top, but cut below it underneath. And finally, to completely eliminate all saw marks (which must be done), I would have a thick, strong, pretty critical part that is smaller than the plans call for. Not gonna do it. New part is $21 plus shipping and is on the way. If that is the most expensive mistake I make, I'll be thrilled. Plus the tapered ends have to be bent 6 degrees, so I can practice on the ruined part first.

I got lucky on HS-710, and could remove all saw cuts and still have a blue line. You can see the difference in image 2. Image 3 shows the other cut pieces after deburring.

Most of my time today was spent at the bench grinder deburring. I can only last a short while before back pain forces me to take a break.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|