|

|

|

|

JoeNelsens Web Site

|

Date: 4-30-2016

|

Number of Hours: 2.00

|

Manual Reference:

|

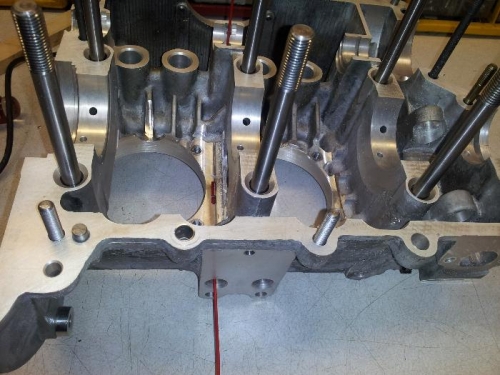

Brief Description: OMG! what happened??

|

|

1) Well, they say this is pretty much normal for off shore manufacturing. And they said not to disturb it. I dont like it, but it should be functional when cleaned up some.

2) Sad story begins here. Look closely and you will see a breech in the casting where the safty wire enters the gallery between the center cam bearing and the rear port to the top mounted oil cooler.

3) A better contrast view of the red straw running from the cam bearing thru the breech and out to the cooler port. The breech should not be there, as it dumps all oil pressure into the interior of the engine, and will never allow pressure to build. I suggest that the machine doing the internal hog-out of excess material to clear rotating menbers, wasnt being attended to properly, and produced excess hogg-out, so to speak!. As tech support said, ..."this is a show stopper." I bet it is! This case was returned. subsiquent info indicated one other case in stock with this problem. The manufacturer of the engine kit sent out a service bullitin to inspect, within a serial number range, cases for this problem, including not built, built not run, run not flown, and run and flying. As far as I am concerned everyone affected should do the inspection befor further flight, but that is just me being cautious. With all the low oil pressure problems on the Sonex net,I think that is good advice. But to each his own. It is experimental aviation and maybe some think lowish pressures are of no real concern. The old horse and water syndrome I guess!

|

|

Not really good

|

|

breecked oil gallery

|

|

look at red straw

|

|

|

|

|

|

|

|

|

Copyright © 2001-2025 Matronics. All Rights Reserved.

|