|

|

|

|

Jerrys Web Site

|

Date: 1-16-2012

|

Number of Hours: 7.00

|

Manual Reference:

|

Brief Description: Wing and Tank Skin Installation

|

|

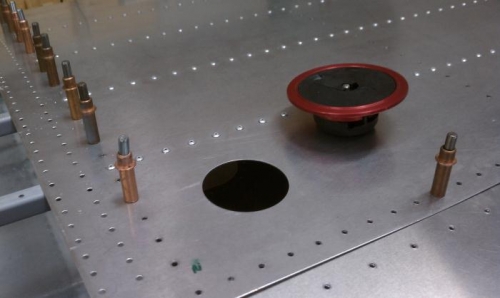

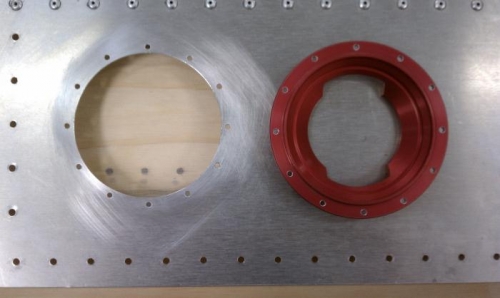

This weekend, I was dismayed to realize the manufacturer had substituted a flush mount gas cap for the traditional flange higher caps. I had to enlargen a hole from 2 1/4 inches to slightly less than 3 inches. In addition, I had to drill 3/32 inch holes with little edge clearance, due to the small 1/4 inch flange on the SPRL gas cap. Well, it worked out ok, I used 3/32 soft rivets and drove them after putting proseal between the flange and the skin.

Then, I prep'd the tank and skin for the final mating. My wife helped spread proseal on the flanges, and we cleco'd the skin in place. I then spent time pulling the countersunk rivets in the root rib, and installed the brackets that enclose the stringers. After all that, I spent time cleaning up tools etc. Proseal sticks to everything.

Tomorrow, I'll rivet the skin in place, turn the wing over, and finish sealing the corners etc. from the two fuel tank access panels.

|

|

The Problem

|

|

Reduced Edge Clearance

|

|

Upper Tank Skin Installed

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|