|

|

|

|

RV-6A - GBC

|

Date: 8-13-2016

|

Number of Hours: 3.50

|

Manual Reference:

|

Brief Description: Fuel System - Operational testing

|

|

Mike C volunteered to assist me with fuel system tests, and we began after the afternoon shade was sufficient to be comfortable in an AZ summer.

We reviewed the procedures and how each task would be accomplished, safety issues, and test details. I operated the controls while Mike observed, watch for problems, and prepared to man the extinguishers. Grounded the plane to the hangar, and the plane to the bucket with a cable to the bottom. (Avoid static build up on the drain tube and discharge to rising fuel.)

Poured 1 gal in the R tank, watched for leaks in the section up to the selector valve, then added another gallon. Selected R tank and then ran the Boost pump with a discharge from the FW fitting into a grounded bucket. Determined that approx 1 qt or less of fuel (unuseable) reminaed in L tank which the pick-up tube could not reach. Carefully added the fuel back to tank, (caught and removed minor sediment), and ran a timed test to calculate free flow capacity with Boost - approx 1.8 gal in 2 mins. (Exceeds 150% of required O-360 TO estimate). Moved fuel to the L tank and repeated all steps, with another small amount of sediment settling in the bucket.

Finally connected teh FW fitting to the engine hoses and pressure tested but did not flow test. Found a loose fitting at the baffle, tightened, and re-checked. Found fuel drips in the intake areas and stopped ... deptermined that AFP procedure calls for Throttle closed, and ICO mixture. Otherwise pressure causes some fuel to leak through - will check with Don @ AFP.

|

|

Prepared to begin

|

|

Flow qty tested - 2 mins

|

|

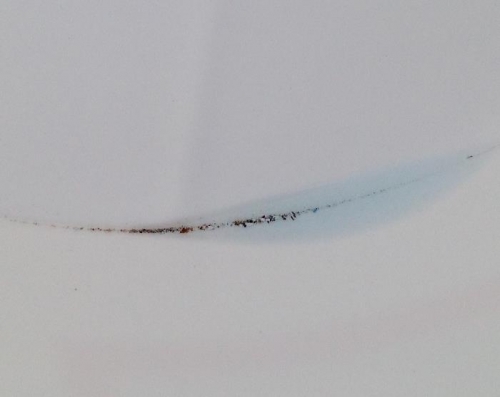

Sediment from flow test

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|