|

|

|

|

Sonex 815 Build Logs

|

Date: 8-12-2006

|

Number of Hours: 5.00

|

Manual Reference: W08

|

Brief Description: Main spar

|

|

Spent about 4 hours to finish the deburring, got out the Avery C-frame dimpler, added the dimples to the .032 web, got out the microstop countersink, and did the countersinking on the .125 web and the upper spar cap. Two things - on the upper spar cap, there's about 8 places where the cap overhangs and the microstop can't be used, so I set up the drill press to make the c-sinks. Came out good enough. And for the 4 bolts that need to be countersunk, a microstop countersink cutter will not achieve the diameter called out on the print. So I set the m-stop to drive the c-sink cutter to about .020" below the surface (a cone hole with a .020 cylinder for the top), and ground out the top part of the cone with the dremel. Worked pretty well. The holes aren't perfectly round, but the vast majority of the bearing surface was formed by the c-sink cutter, so it looks like it will work fine. Got the spar all clecoed back together. Spent the last hour or so assembling the 12-ton hydraulic press (Harbor Freight) to use as a rivet smasher. At this point, the bare press won't do it. I need to make holders for the actual rivet-smashing bolt (I'll use the rivet driver from the Avery c-frame and also have two straight rivet sets that I might try) and something to stabilize the spar and Sonex bucking bar.

|

|

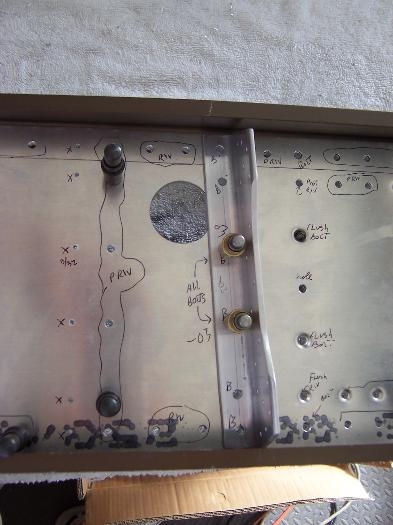

Root end, all dimpled and countersunk.

|

|

Close up of root rib attache and c-sunk bolts at wing pin block.

|

|

Forward side of the root rib - on LHS root rib angles protrude on flap pushrod hole.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|