|

|

|

|

Andrews Web Site

|

Date: 11-9-2023

|

Number of Hours: 8.00

|

Manual Reference:

|

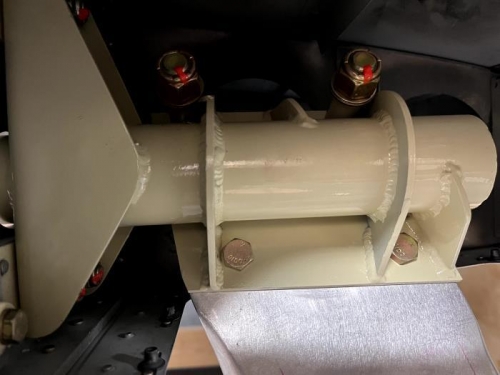

Brief Description: Final gear leg mounting

|

|

The landing gear legs were permanently mounted. I few thoughts on this. As mentioned, I did not stress relieve my gear weldment after fabrication. However, I did relieve the fit of the gear leg prior to installation. Let me explain. When the gear leg weldment was fabricated, it warped...because it is a weldment. Welds tend to pull metal inward when they cool so this tries to bend the mounting plate that will eventually bolt to the gear leg. If I had stress relieved the weldment, the best I could hope for if things were perfectly done in an oven etc., is that the preload in the weldment would be reduced...but the warp would still be there. Now, when the aluminum gear leg is bolted to the weldment, it would try to straighten the weldment back out because the weldment is a convex shape that is being pulled flat. This would add preload. What I did on my installation is to add a minor dish between all the bolt holes. Image 1 shows a cross shaped pattern between the holes, and image 2 shows the degree of relief added (approx. .030). When the weldment is bolted to the gear leg, the warp in the weldment will not add additional preload when the bolts are torqued. I think that even if the weldment had been stress relieved, if the gear leg was not dished to accommodate the warp, you still end up with preload. So, I at least did not add that. Image 3 shows the final bolt installation. Bolt direction dictated by installation clearances.

|

|

Cross pattern of dishing on gear leg

|

|

.030 relief added

|

|

Final gear leg installation

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|