|

|

|

|

Todd's Web site

|

Date: 12-26-2005

|

Number of Hours: 2.50

|

Manual Reference:

|

Brief Description: Rudder work

|

|

Finished deburring and dimpling of the rudder skin. I'm pretty much done with that until I get the skin and stiffeners primed, so I continued with the fab and preparation of the rudder skeleton parts. I got good practice at laying out and trimming the R-716 bottom fairing attachment pieces and the R-717 shim on some .020" sheet. The only problem was it was supposed to be .032" aluminum. So I got to hone my laying out and trimming skills of those pieces again.

Cleko'd, match drilled, trimmed, fluted, and fit all the skeleton pieces I could until I got to the point I had to start attaching the skin for further fitting and drilling. I can't fit the skin until I get the trailing edge bent. I can't bend the trailing edge until I rivet the stiffeners on. I can't rivet the stiffeners on until I prime them and the skin. Soooo, it's time to to some painting. I hope I get better at it. I figure I'm about an 80% painter--that is, when I paint, about 80% of it turns out decent--the other 20% pretty much stinks. Oh well, it's just a matter of doing it and getting practice at it. The good thing is that these are all internal parts nobody will be seeing, I just need some good corrosion coverage.

|

|

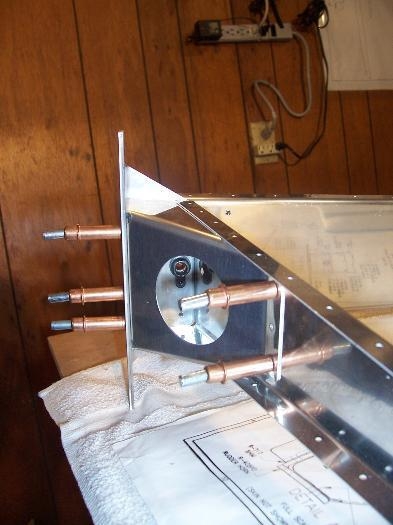

Rudder horn area

|

|

R-716's and R-717

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|