|

|

|

|

Jean RV6 Construction Log

|

Date: 1-24-2021

|

Number of Hours: 12.00

|

Manual Reference:

|

Brief Description: Drilling the roll bar

|

|

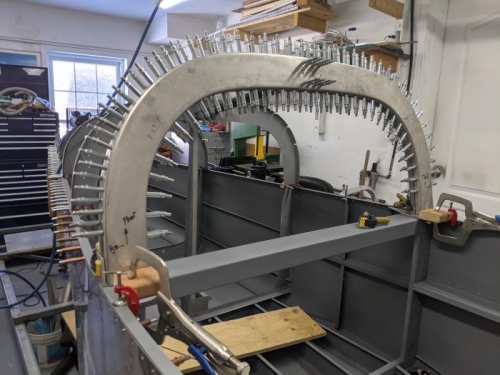

Yesterday and today, I worked on the roll bar, an important structure , which is not complicated but does take a long time to drill and fit properly. As you can see I have not yet done the final drilling as I like to prepare the work with smaller holes which leaves place for some adjustment if needed.

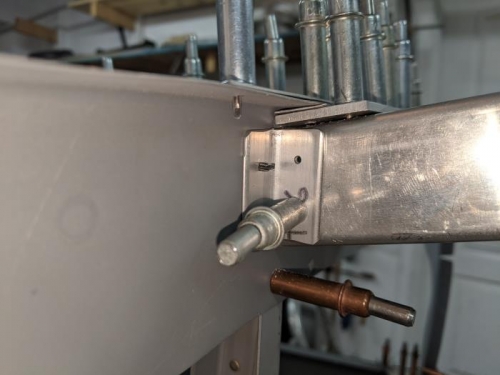

On the first picture since the roll bar thickness is 1 1/2", I have used my pluber pliers which have adjustable jaws that I set at 1 1/2", so I insure to close the gap evenly all across the roll bar. It worked well.

On the second picture I am showing that instead of using the 1/8" angle to attach the large bar behind the roll bar, I used the system that is in place for the RV7. Much easier to install. It is important to read the plan well because if you notice, there is a 0,032" spacer between F606 flange and the thick spacer.

Some details are not yet fixed; as an example, the small angle will be grind to follow the shape of that thick bar you can see on the second picture.

Next weekend, it will be the final drilling, cleaning, dimpling or countersink, priming before getting on the skin drilling.

|

|

Adjustable plier jaws

|

|

See the 0,032" spacer ?

|

|

It is quite fun to see that structure !

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|