|

|

|

|

RV-7

|

Date: 12-22-2012

|

Number of Hours: 6.50

|

Manual Reference:

|

Brief Description: HS assembly

|

|

"The big day .. Finishing up the HS. Cleco'ed and riveted per the instructions. Good performance throughout. Really like the new tungsten 4x5/8x1/2 bucking bar, easy to handle and use. Practice found tha the bulk of the force should be on the gun, with a light restoring force on the bar to keep it on the shop head. It's easy to push on both equally, which sometimes results in the head of the rivet popping up a bit. 35 PSI on the 3x with a mushroom set worked well. I don't think the 0.032 skins dimple that well with the c-frame or squeezer; they just don't seem deep enough. For the edges where I used the squeezer, I hit the holes with the microstop countersink just to shave them very slightly, and the seem to set better. Had one reall bad rivet on the bottom of the HS skin, and kept drilling it out 3 times .. crap! The hole was so big that I decieded to do a litte bit of extra countersinking and put a size 4 rivet in (after some trimming). Looks fine, and actually a bit hard to see unless you know where to look. Gotta get some oops rivets!

In the final assembly step, I put in the pop rivets for the mid rib. They didn't go it very easily ...though it was the primer, so I pushed hard. Turned out that this process caught the edge of the flange on the rib and pushed it away from the aft spar. The pop rivet didn't engage! So, I drilled them out and inspected throught the holes in HS-404. The flanges are still bent away from the aft spar a bit. Need a way to push them back."

|

|

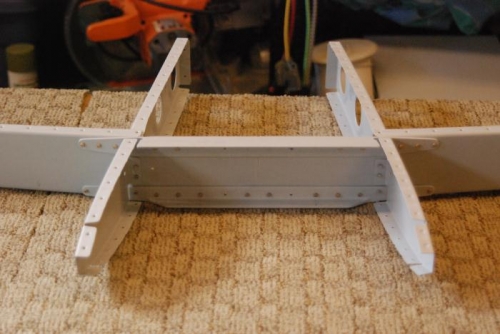

Frame riveted

|

|

Skins going on...

|

|

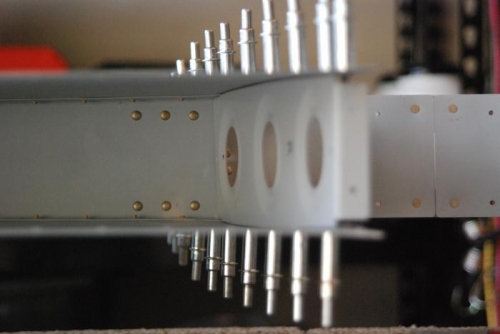

Inside view

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|