|

|

|

|

Stevens Web Site

|

Date: 11-11-2006

|

Number of Hours: 3.20

|

Manual Reference:

|

Brief Description: Started working on 807 Bulkhead

|

|

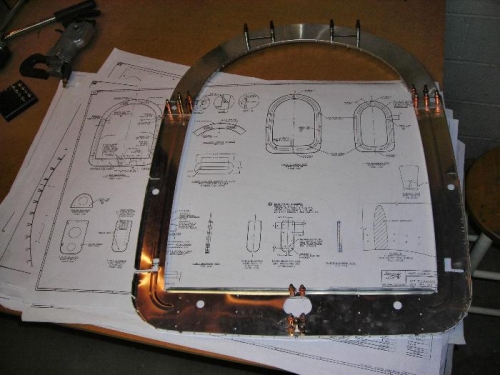

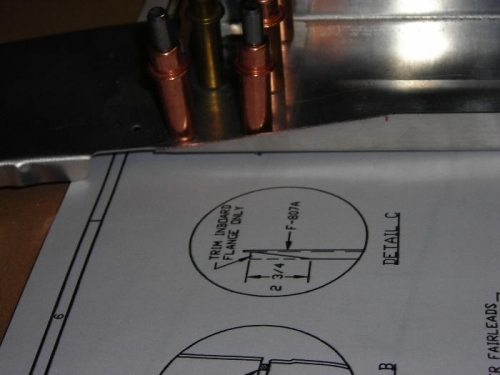

Before really getting to work tonight, I drilled out and reset about 1/6 dozen rivets in the firewall that looked a little funky. Now that those rivets are finished, I can set the firewall aside for attachment to the jig. Next, I started on the 807 fuselage bulkhead. This is the bulkhead that goes directly behind the rear passenger. First, I had to trim away some parts of the pre-stamped pieces. Next, I had to flute the pieces so that the bulkhead will lay flat. As you may remember, when these parts are pressed out in a giant press, the bent flanges make the part warp like a potato chip. By fluting the part (bending little scallops into the flange) you can make it lie flat so that it will fit into the fuselage structure correctly. Next, I spent some time fabricating the fairleads which will be riveted to the 807 bulkhead and will serve as doublers for the slot where the rear shoulder harness belts go through. Then, I drilled all of the parts together and clecoed them for riveting later. Finally, I tapered the inside flange of the bulkhead at the top joint so that the rear seat will be able to fit flush.

|

|

The 807 bulkhead all drilled and clecoed together

|

|

The rear shoulder harness fairleads which I had to fabricate from .063 aluminum plate

|

|

The inside flange is trimmed so that the rear seat will fit flush

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|