|

|

|

|

Steve & Nancy Riffe

|

Date: 12-5-2015

|

Number of Hours: 4.00

|

Manual Reference:

|

Brief Description: R.wing coiled vent tube

|

|

Early on in my build, I had decided to use a coiled tube in the wing root for the fuel vent system as opposed to running the fuel vent from the wing into the fuse up and then down the gear tower and finally out the bottom of the fuse. The Rocket guys use the coiled tube as well as other RV builders, so I thought I’d give it a try. Starting with the right wing, I attached a short stub to the fuel outlet to get an idea of where to run the vent line. There is not enough skin available from the edge to the rib flange to put an exit point, so I fabbed a small piece to rivet to the skin and also attach to the wing root. After getting the tubing bent, shaped and cut to length, I flared the end and attached to the fitting from the tank. I put a joggle in the vent line support, then match drilled three #40 holes thru the skin and support. I marked the location for the exit point on both the support and the wing root as well as a location to install a nutplate on the support. I opened up the vent line hole with a step bit and drilled the attach hole to #19—used a nutplate jig to drill holes for attachment, cleaned up dimpled, primed etc. I riveted the nutpate to the support, then riveted the support to the tank skin. I installed a snap bushing in the support, then installed the coiled vent. The wing root fairing slips over the extended tube and is then secured with a #8 screw—seems stable enough. I still need to trim the vent tube where it exits the fairing and then cut to a 45 degree angle.

|

|

Bent vent line, began fabbing support

|

|

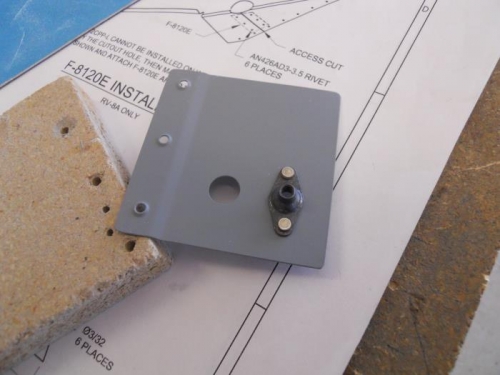

Support ready to install

|

|

Vent system installed with wing root in place

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|