|

|

|

|

Chris and Karens RV-6A

|

Date: 5-19-2007

|

Number of Hours: 10.00

|

Manual Reference:

|

Brief Description: Riveting skin to spar and bending trim tab ends

|

|

I decided to bend the ends of the trim tab BEFORE completing the trailing edge bend of the tab.

This way, I could clamp form blocks inside the skin and bend against these. With a small radius on the block along the bend line, and about 7degrees 'over bend', the resultant bends were really close to 90deg. I also 'offset' the location of the block when bending one side (top/bottom) relative to the 1st, so the finished tabs wouldn't interfere with each other when the trailing edge bend was completed

In the 1st picture, the elevator has been partially riveted to the spar. There are a bunch of rivets not yet installed, starting near the center, span-wise, where the skin is 'peeled back' from the spar.

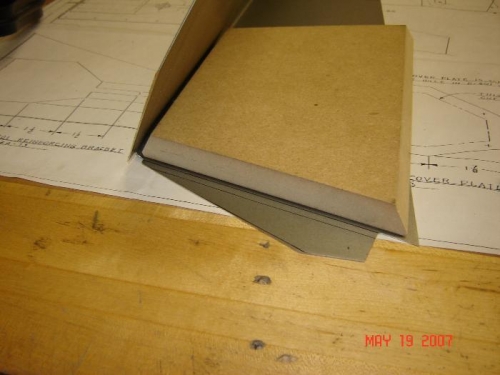

The 2nd picture shows the form block of MDF used to complete the bends that form the inboard end of the trim tab. Notice the small 'flat' spot at the widest end. Regardless of doing things as specified in the manual and wasting NO extra material (the skin was cut from the elevator skin using a 'knife' for cutting/scribing plastic sheet. Many repeated passes resulted in wasting almost no material (as far as width of cut). The form block is cut symmetrical, so flipping the block end-for-end allows it to be used to bend the trim tab on the other side (top/bottom) of this same end.

3rd picture, similar, but smaller block made of oak for bending outboard end tabs

|

|

Elevator in jig, partially riveted to spar

|

|

Form block for bending inboard tabs

|

|

Form block for bending outboard tabs

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|