|

|

|

|

Project Blue Angels SeaRey

|

Date: 11-13-2013

|

Number of Hours: 6.00

|

Manual Reference: None

|

Brief Description: Pitching the prop

|

|

Alright... back in business; had to take care of some other stuff for several weeks there.

My ECUs for the engine finally came in, so I spent the day redo-ing a bit of wiring for that, and I want the prop to be nice and balanced when I start the engine, so I set the blade pitch. From what I understand with this 66" prop, 13 degrees is about where you want the pitch, but I set it to 12.5 to account for the Florida heat, and I rather set my pitch to have full RPMs available in the beginning, and back off a bit, than not have enough.

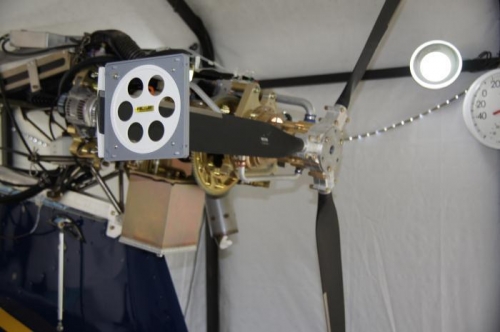

Another thing I did, I found the brushings in the prop extension would spin as I'm trying to tighten the bolts, so I have to try to keep them still by wedging a flatheat screwdriver in the other side as I tighten. I took the Dremel and carved-out a small channel in the brushings to fit the head of the screwdriver, so they'll stay still. And one more thing... the prop bolts get hidden behind the spinner so they'd be hard to properly inspect before each flight. I bought longer 80mm X 8mm bolts with holes drilled in the heads, so I can safety-wire them in place. Torque prop bolts to 175 inch/pounds.

4/6/2014 EDIT: After my first couple of flights, I see that 12.5 degree pitch was giving me 5700rpms on takeoff, but over 6000 in the air. I have repitched to 13 and waiting to test (should be about right).

|

|

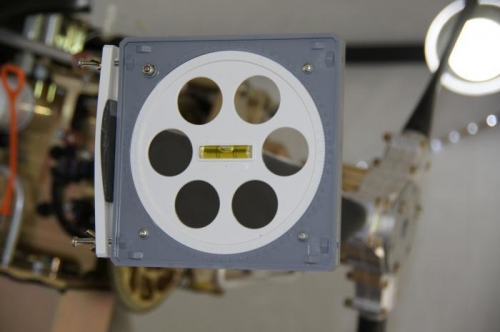

I measured that the hub was slanted at 13 degrees, so I set the tips at 0.5 to get 12.5 pitch

|

|

Pitching is easy once you get the hang of it

|

|

Modified brushings and drilled bolt heads

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|