|

|

|

|

REX'S WEB SITE

|

Date: 9-16-2016

|

Number of Hours: 4.00

|

Manual Reference:

|

Brief Description:

|

|

Got a late start today, but good progress. Ordered a 3 flute #40 countersink from Cleaveland Tool yesterday, but must have missed the last pickup, as it didn't arrive today. It's job is to create a countersink in a piece of steel so I can dimple the last three holes in R-904 rib using a rivet gun set. Called Cleaveland tool to ask if using my single flute countersink in steel would damage it. They said it wouldn't damage it, but would dull it. Hence the ordering of the 3 flute countersink for the one off job.

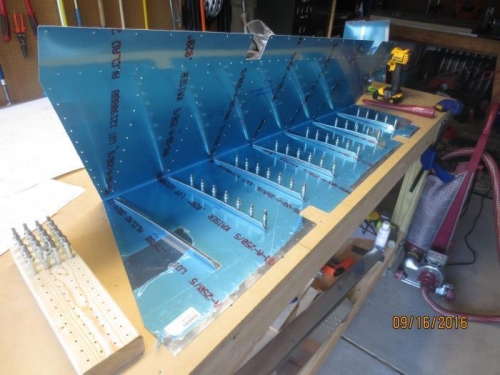

Since it didn't show up, decided to match drill elevator stiffeners, starting with the right side. 3 of the stiffeners have to match drill the aft hole from the skins. I did that first, then drilled into the bench, just like the rudder. My primary drill is a DeWalt 20v. It is awesome, but much more bulky than a pneumatic drill. I didn't feel comfortable bending the skin enough to drill the last hole in each stiffener. Then I thought if I am drilling 3 stiffeners from the skins, why not all of them? So I clecoed the stiffeners to the skin and match drilled the aft two holes of each one from the outside.

Enlisted construction supervisor Gary to help with the left elevator. It has a large notch cut out for the trim tab, and is very floppy. Having another set of hands is invaluable. Again match drilled the aft two holes of each applicable stiffener from the outside.

|

|

match drilling last hole in stiffeners

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|