|

|

|

|

Marlins Web Site

|

Date: 2-27-2019

|

Number of Hours: 17.00

|

Manual Reference:

|

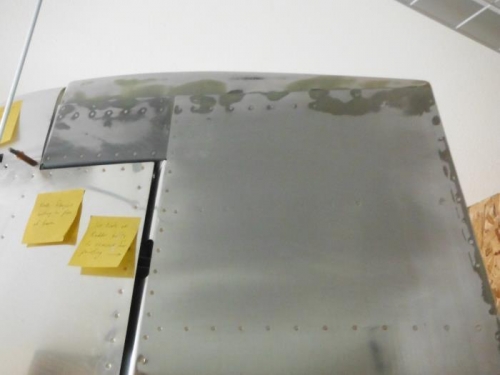

Brief Description: More Cosmetic Body-Work

|

|

I went on to fill epoxy over the heads of all the flush pop-rivets and adjacent rivets. This way, the entire surface will be consistent and no rivets will show under the paint where I had to use pop-rivets. I also created a huge 1/64" deep, 3” wide dent when I was stretching the skin over the avionics bay. I must have pushed on the skin with the palm of my hand or leaned on it with my elbow. It wasn’t obvious under the protective plastic but when I pulled the protective covering off (after riveting), I realized why the rivet holes didn’t line up very well. Additionally, many of the preformed fiberglass parts didn’t fit perfectly to the metal and I also wanted to cover the pop-rivet heads. I know most guys will fill these in with fiberglass-flox, but I decided to use the polyester-epoxy filler and won’t have to deal with pin-holes in the fiberglass. It doesn't look great in these pictures, but when it is all painted, it will create a superb finish. Also, none of this body work is covering up any structurally inferior rivets, it's just because I want the paint job to really look awesome. This afternoon I’ll finish cleaning up the shop from all the filler-work and tomorrow I will figure out a way to keep the canopy at a consistent temperature over 80F; using space heaters. Once I’m sure I won’t crack the canopy, I’ll start to make all the cutting and drilling measurements and drill the hole for the latch.

|

|

Covered All Rivets for Consistency

|

|

Pop-Rivets on Fiberglass

|

|

Fiberglass Interface on Rudder

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|