|

|

|

|

Michaels Web Site

|

Date: 4-14-2023

|

Number of Hours: 1.25

|

Manual Reference:

|

Brief Description: LEFT fuel sender float

|

|

I used pieces of metal coat hangars to test the bends needed for the float to read full and empty. It took a lot of trial and error, but I finally came up with something I was happy with.

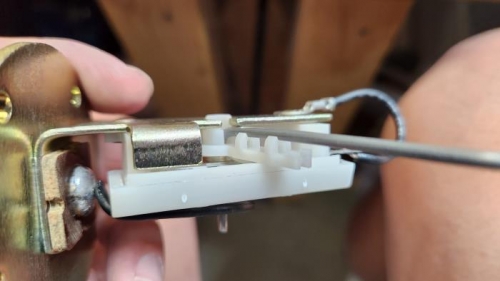

So I transferred the bends to the wire arm of the float, and made the bends. The float arm is MUCH stiffer steel than the coat hangers, and the coat hangers are a little thinner. When I went to put the 90 deg bend into the sender body, I found the bend radius was too large to fit! The plastic body of the moving arm requires a nearly 90 degree bend, something the instructions never point out.

I tried hammering the wire over an anvil to try to get a 90 deg bend, but nothing worked. I've ordered a new float arm so I can try again, but I need to reach out for help/ideas on this. I could use my welding torch and heat it to bend it 90 deg around a steel edge, but I'm afraid I'll accidentally cut through it, or that the heat transfer will reach to, and melt, the float.

|

|

Multiple iterations with sections of coat hanger

|

|

The final coat hanger bends

|

|

Radius too large! Wire won't seat.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|