|

|

|

|

Kupe's Zodiac 650B

|

Date: 12-22-2017

|

Number of Hours: 3.00

|

Manual Reference:

|

Brief Description: Left Flap Installed

|

|

Finished installing the left flap. Trimming the left torque tube seemed to do the trick. Re-installing the piano hinge wire was a significant challenge for the last 4 inches or so. For the right wing, I chucked the wire into my and drill and fed it through the 7 feet (or so) of hinge and tapped in the last 4 inches with a hammer. The left wing pin seemed much tighter so that the last 4 inches required more than a hammer. I had to drill out the threaded end of an AN3 bolt so it would hold the hinge wire end snugly. This gave me a much sturdier hitting surface (a bolt head) for tapping the wire in that last 4 inches.

In preparation for drilling the torque tube, I moved the flap motor to the full up position, propped up the left flap to full up, and made sure the pin on the torque tube end was all the way up inside the slot in the inboard end of the flap. From there I crawled up inside the belly access hole to drill through the steel torque tube, twice, to bolt it into position with both flaps aligned to each other. With the flap motor mounted just behind the pilot seat, it's a challenge to rest on one's knees with head and shoulders crammed under the baggage shelf, using a Tight Fit 90 degree drill attachment to drill through the steel pipe. After 5 minutes with little success, I've determined my drill bits for this task (3/32" pilot, 3/16" final) are woefully dull. New ones are on order. In the meantime, I reviewed a few YouTube videos describing good practices for drilling through steel.

|

|

Left flap installed. It took considerably longer to get the piano hinge pin into this one.

|

|

Left flap set to full up position for torque tube drilling.

|

|

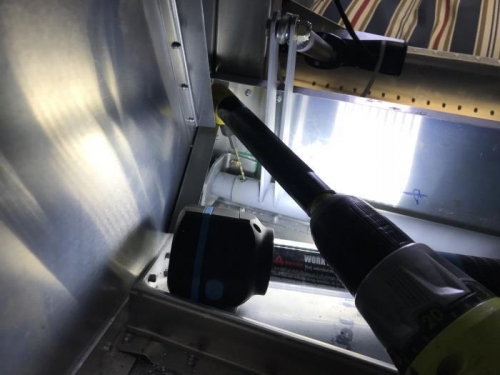

Flap torque tube behind pilot seat with 90 degree drill bit posed. Very tight quarters indeed.

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|