|

|

|

|

ALAN'S WEB SITE

|

Date: 12-4-2008

|

Number of Hours: 2.00

|

Manual Reference: 34A

|

Brief Description: Stick Boot Ring

|

|

This evening I started work on what looked like a simple fabrication task, making the stick boot ring. AGH! This is the first time I've had to trim any large area out from a piece of metal. I'm sure there are better and faster ways of doing it... but here's how I did it.

First, I measured everything out on som AS3-062. It amazes me that they use measurements down to the 32nd of an inch for the stick boot ring. Next, I trimmed the piece down to size. I used the big break Cormac has in the hangar. I'd watched him work it last weekend and I wished I would have known how to use it sooner. It trims metal like a hot knife through butter.

The part you trim out from the middle has corners with a 1/4 inch radius. So, trying to be exact, I measured carefully and drilled a small hole. Then, increased the bits by 1/64 of an inch to slowly make it larger. Stupid move - it makes a better hole if you just drill the dang thing. (Luckily, it turned out OK.)

After measuring and drawing the part to trim out carefully, I drilled some 1/3 in holes near each corner. Then, I used a step drill to enlarge them to 3/4 of an inch. Enough to get the tin snips started. I used the snips to work my way up on the line.

Even though I was careful, the line wasn't perfectly straight so I clamped it in the vice and filed it smooth.

|

|

I used Cormac's super duper metal cutter - cool

|

|

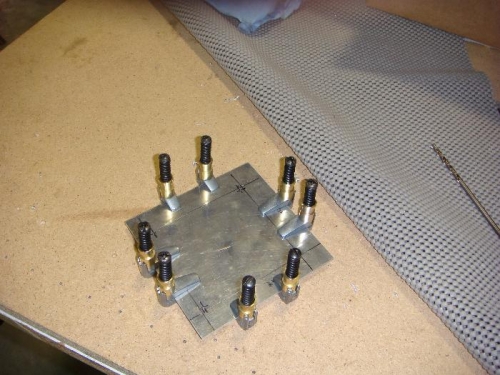

Clecoed to match the pattern

|

|

9110 clamped in vise (my dog is ready to head home:-)

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|