|

|

|

|

Kurt Haller RV-9A

|

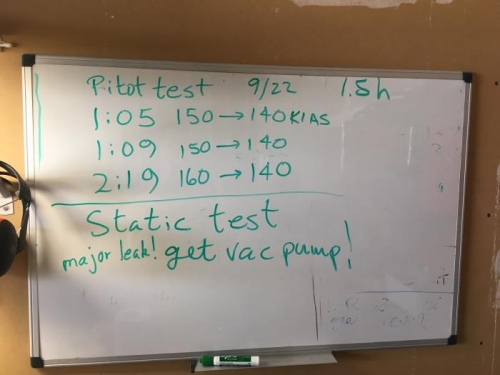

Date: 9-22-2018

|

Number of Hours: 1.50

|

Manual Reference:

|

Brief Description: Pitot/Static Leak test

|

|

Got several air "needles" from McMaster to fit inside pitot and static ports. Used squares of 40A durometer, 1/32" thick silicone rubber sheet to seal (image 3). Overall view of static test rig in image 2. The static port on the other side of the fuse was covered with a silicone square held in place with duct tape.

With the needle in the pitot (not shown), the 10' latex rubber hose reached the cockpit. Clamping the end and pinching the tube was enough to register 40 KIAS on the ASI. Applying another clamp to hold the pressure, the reading held steady for several tens of seconds. But wrapping the tubing several turns about a mandrel to get > 160 KIAS, there was a leak of < 10 KIA/min, as seen from the data in image 1. Meets the FAA guideline, but just barely. Need to investigate after first engine start when I take all the covers off again for final inspection. It may be the bungees holding the needle to the pitot were too weak to seal 100%?

Back to the static system. The 5/16 ID, 3/32 wall thk, 40A durometer latex wasn't as flexible as I had hoped. Could not create vacuum by pulling tube through squeezing fingers. I could use a "rolling pin"on the tube against the hangar floor (that's what the spray can in image 2 was for), but vacuum didn't hold at all. Massive leak! Instead of the vac pump suggested in image 1, I'll bring a syringe on Sunday and try again. Driving home, I realized I didn't check that the alt static valve on the panel was closed. Would be nice if it was open and closing it does the trick.

|

|

Pitot leaks--but meets FAA guideline

|

|

Static test

|

|

Close up of static fixture

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|