|

|

|

|

Kurt Haller RV-9A

|

Date: 10-28-2006

|

Number of Hours: 7.00

|

Manual Reference: 6-2, 6-8

|

Brief Description: Horizontal stabilizer; Left elevator trim spar

|

|

Went back to the horizontal stab today. The csks in the spars, which were done "by hand", turn out to be too shallow (as well as non-uniform). The skin sits proud more than 0.007". I re-countersunk the lot, finishing three of four spars today, as well as re-countersinking the trim tab spar, which had non-uniform holes that were also too shallow.

It took so long because I tried making a jig for the drill press, but in testing the vibration was just too big...when I measured runout with a dial indicator, it was more than 0.010"!

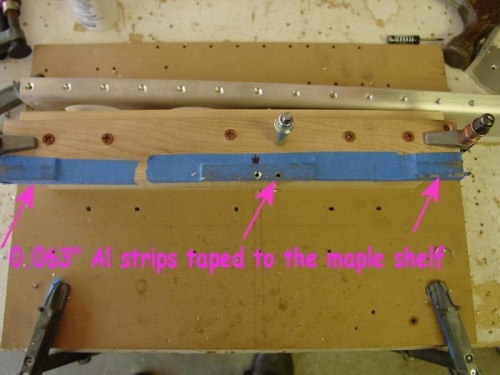

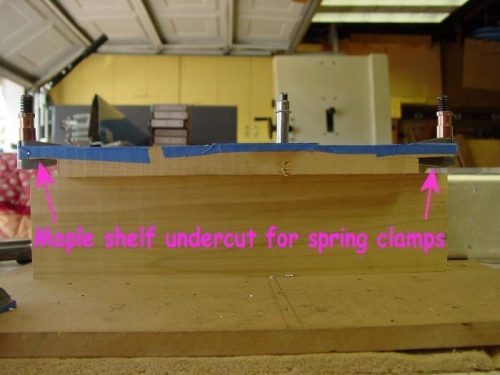

I switched to using the jig in the photos with the microstop in an electric drill. (More photos in next entry explain its use.) It was tedious to csk the holes one at a time with six clamp moves in between. (Release the two spring clamps, index hole to the pilot support hole with a cleco, re-set the spring clamps, remove the cleco.) But the csks came out absolutely uniform. Cleaned up the chattered holes at the spar ends too, using a piece of 0.063" Alclad--same thickness as spar--to support the foot of the microstop.

I snuck up on the correct depth veeerrry slowly. I clecoed test holes to the stab skin--it looked OK with no "play". But after finishing a row and clecoing the whole thing...still proud. Made a piece of test "skin" (seen in foreground of photo 3) and made sure the csk was deep enough that a 0.002" shim would not go between skin and spar.

|

|

Top view of csk jig

|

|

Side view of csk jig

|

|

Ready to remove cleco and csk

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|