|

|

|

|

Kurt Haller RV-9A

|

Date: 12-2-2018

|

Number of Hours: 3.50

|

Manual Reference:

|

Brief Description: Taxi test; depanel da plane

|

|

Taxi test and brake conditioning! John G. graciously assented to becoming a named insured and took the right seat, just in case anything went south. It didn't. Taxied to Juliet, tower cleared us for taxi with braking. Had done 3 snubs by time we got to Charlie. Tower cleared us to 25R run up area. Brakes held fine at full static run up, 2260 RPM. Then taxi back to hangar and shut down. Max oil T 152 F. Oil p 51-73 psi. Max CHT (during full power) 361-341 F, w/ fuel pressure 29 psi and flow 10.6 gal/h. Again, cyl #4 was coolest...need to recheck probe assignments. Taxi test was a whopping 20 m, startup to shutdown. 0.5 on the Hobbs, 0.3 on the tach.

DO BETTERS: 1) Differential braking for the steer took some getting used to. John G recommends rudder pedal extensions. 2) Flipped flap switch up before starting to taxi, and it was up when we shut down. Completely forgot to center it off. I trained so long in C172's and their automatic flap controls maybe I should go with an electronical version after all. 3) I only told the tower that "Cessna 8PK" was calling ONCE.

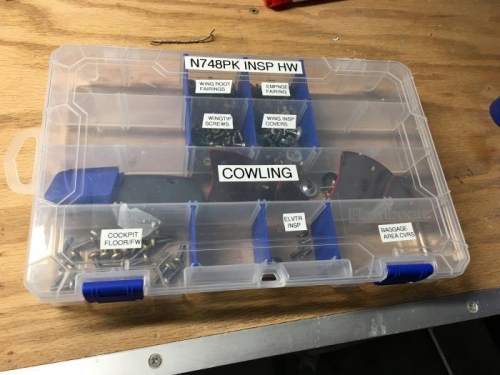

Spent rest of the day completely decowling, opening all wing inspection panels, taking out wingtip screws (left 4 clecos in each side to hold them in place). Found black foam ty-wrapped to aileron pushrods--used for cushioning when wings installed--removed. Got a compartment box to store the hw fastening panels and whatnot to the airframe. If box isn't empty after inspections, something's missing!

|

|

Non-virgin brakes

|

|

Opening all for inspection

|

|

HW box for inspections

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|