|

|

|

|

Kurt Haller RV-9A

|

Date: 7-10-2016

|

Number of Hours: 6.00

|

Manual Reference:

|

Brief Description: Spring return for fuel purge valve.

|

|

In case the cable to the fuel purge valve ever fails in flight, a return spring to hold it in the RUN position, assuring normal fuel flow to the engine, is advised. Some folks have attached extension springs to the purge valve lever arm, anchored at the other end to something Adel clamped to a pushrod cover tube or to the baffles.

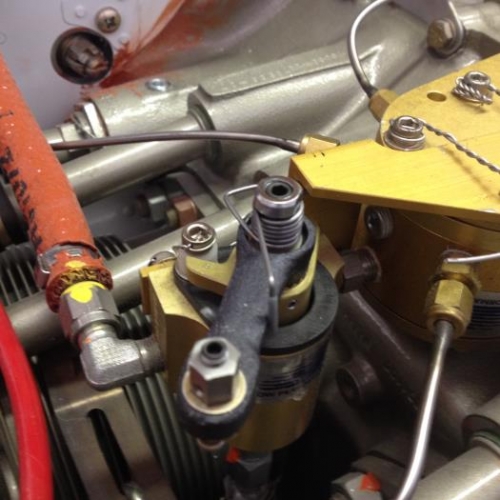

A more compact solution is the torsion spring I fabricated from 0.047 music wire, shown in image 1. The funky bends on the left leg of the spring cradle the purge valve lever arm as shown in the slightly out-of-focus foreground of image 2. On the right leg, a 90 degree bend closest to the coil aligns with the vertical face of the bracket supporting the purge valve from the top of the fuel spider. As installed, the torsion spring legs deflect about 40 degrees, providing pre-load to keep the valve firmly in the R position. The next two bends along the right leg align the terminal 90 degree bend with a drilled hole in the purge valve bracket, which firmly anchors the right leg (image 3). Heat shrink on the leg ends provides anti-chafe where the spring wire contacts lever arm and bracket.

The bottom of the coil encircles the ¼-28 metal locknut nut that secures the lever arm to the purge valve stem. As a keeper for the coil, I fabricated a flanged bushing, with a ¼-28 thread running through it, which screws onto the stub of the valve stem above the locknut. Two flats were filed onto opposite sides of the flange to fit a 3/8” wrench. This holds the bushing when torqueing the set screw at the top of the bushing which bears on the valve stem, locking everything together. For additional insurance, blue Loctite was applied to the bushing and set-screw (and the set-screw in the Bowden cable nut as well).

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|