|

|

|

|

Jim's Web Site

|

Date: 8-10-2014

|

Number of Hours: 13.00

|

Manual Reference:

|

Brief Description:

|

|

This is a multi-day post, as I have been, frankly, lazy about posting. But progress is being made. As of today, I've potted in all but two ribs, and have reinforced the inboard nose rib, the one that takes a 14 bid layup. One issued I faced was with the BL 120 tail rib, which requires that all but one inch of the core and one side to be removed, in anticipation of a 7 bid reinforcement after mounting. This is a flap hinge mounting rib. Problem is that when you remove all that structure, the remaining side curls rather dramatically, making mounting essentially impossible. I tried flattening it out in the oven, but stopped when 250 degrees did not faze it in the least. This material is post cured, and you have to elevate the temperature above the post cure temp, a number I don't know. It's obviously above 250 degrees though. Anyway, my solution was to add 3 bid to the curled side, and sandwich the layup between pieces of wood, with release tape applied. This works. There is a weight penalty, but it's negligible.

|

|

Inboard nose rib, reiforced, before trimming

|

|

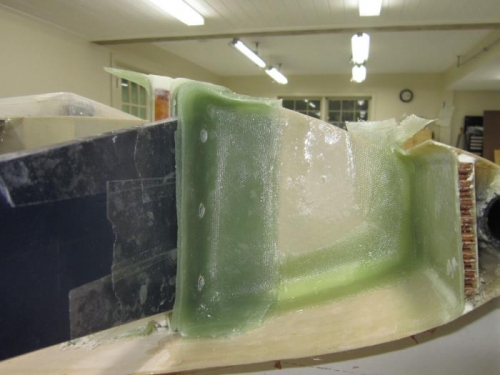

BL 120 tail rib, reinforced to eliminate curl, before trimming

|

|

Five of six flap ribs potted in, waiting for cure

|

|

|

|

|

|

|

|

|

Copyright © 2001-2024 Matronics. All Rights Reserved.

|